New downhole model for geothermal launched at Drilling Simulator Celle

Drilling Systems, part of 3t Energy Group, has launched a next-generation DrillSIM Downhole model to support realistic training for geothermal applications. The model has been implemented at the Drilling Simulator Celle (DSC), a research facility of Clausthal University of Technology (TUC), in Germany.

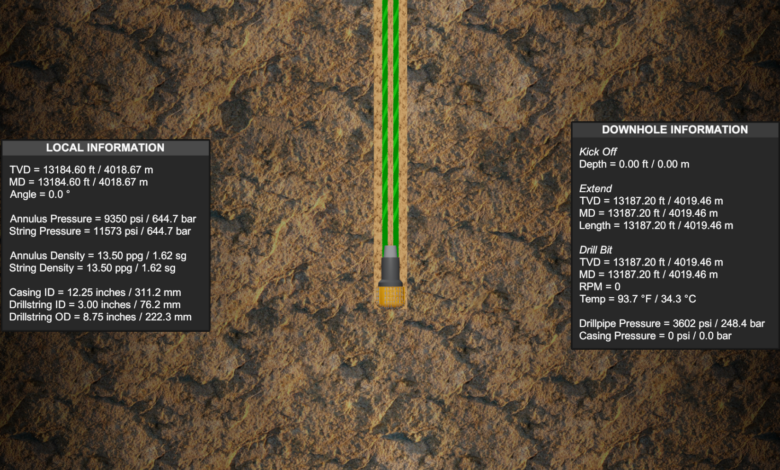

This next-generation downhole model will further enhance the research and development capabilities of new and existing DrillSIM simulators to allow delegates to practice complex operations, such as directional drilling, kick tracking and stuck pipe, in a highly realistic and detailed virtual environment. Key features include additional real-world data modeling, an advanced thermal and dynamic design, drill string vibration, a complex 3D well path and increased focus on the transport of cuttings commonly found in deep drilling operations.

Supported by funds of the Federal Ministry for Economic Affairs and Climate Action in Germany, this collaborative research project saw DSC elaborate the basic principles and mathematical formulation of the model, which is based on simulations and experiments. This allowed Drilling Systems to develop and provide the DrillSIM application programming interface (API), which allowed students to write and integrate programs in C# and Python to alter the behavior of the simulator. Working closely with TUC, Drilling Systems worked to advance the functionality of the API, building upon and strengthening the capabilities of the DrillSIM Downhole Model to support more complex and detailed operations.

Commenting on the success of the project, Clive Battisby, COO of Drilling Systems, said: “Having worked closely with the university since 2015 providing our advanced cyber simulator the DrillSIM:600, we understand the university’s drive to further its research, and we are proud to be a part of this exciting journey. In high-hazard industries like oil and gas, the risk of human error can be fatal meaning the level of detail in our simulators is absolutely essential to ensuring personnel feel confident and well-equipped for work out in the field.”