Drilling & Completion Tech Digest

First multiclient wide-azimuth survey launched offshore Mexico

Schlumberger has launched what it calls the industry’s first multiclient wide-azimuth survey offshore Mexico. The survey will cover 80,000 sq km using two fleets of WesternGeco vessels.

“We have begun acquisition of high-quality seismic images of the Campeche Basin, which when combined with advanced modeling and interpretation, will help our customers identify new exploration opportunities and minimize risk,” said Maurice Nessim, President of WesternGeco.

Subsurface challenges in the Campeche Basin, including near-salt and subsalt structures, complex faulted structures and deep-thrusted structures, are overcome using a suite of wide-azimuth, long offset and broadband seismic surveys. In such complex geology, where illumination of the subsurface is challenging, wide-azimuth acquisition and broadband imaging technologies deliver advanced data to support identification of subtle structural and stratigraphic traps, provide better delineation of fractures and improve reservoir characterization.

GE, Statoil launch open innovation challenge on water management

GE and Statoil’s Sustainability Collaboration has launched the call for entries for its second open innovation challenge, focusing on water usage in the development of onshore unconventional oil and gas reservoirs. The challenge seeks to find innovative solutions for both reducing fresh water usage and treating and reusing water from development activities – while maintaining or improving productivity.

The collaboration was launched in January as an ambitious joint technology-focused program to drive industrial solutions to some of the biggest challenges facing global oil and gas production. The initiative seeks to reduce the environmental impact of oil and gas development and production by accelerating the development of environmentally and economically sustainable energy solutions.

In this challenge, up to five winning entries will win a prize of $25,000 each and the opportunity to be eligible to receive additional funding. Additionally, GE Oil & Gas and Statoil will leverage their joint assets and resources to support the commercialization of the winning submissions.

284 vertical-curve-lateral, single-run wells drilled

Over the past 18 months, Weatherford International’s Revolution rotary steerable system (RSS) has drilled 284 vertical-curve-lateral wells in single runs, totaling 2.4 million ft. The system works in HPHT and high-dogleg applications.

The technology has completed several projects in the Eagle Ford Shale in Texas. In a recent onshore horizontal well, the Revolution RSS was used to drill a well through a challenging, dense limestone and sandstone formation to a total depth of 16,559 ft (5,014 m) and high temperatures up to 328˚F (164°C). The average rate of penetration was 75% faster than conventional steerable motor assemblies.

On a separate project with six wells in the Eagle Ford, Revolution RSS achieved an average of 180 ft/hr (55 m/hr) on all six wells and a record of 227 ft/hr (69 m/hr) on one well, reducing the drilling cycle by two weeks and saving the operator more than $1 million in operational costs.

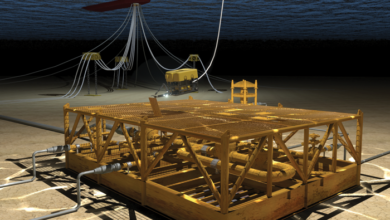

OneSubsea to supply industry’s first 15,000-psi subsea pump system for Stones development in GOM

Shell has awarded a contract to OneSubsea, a Cameron and Schlumberger company, to deliver the industry’s first 15,000-psi subsea pump system to be installed in the Stones development in the Gulf of Mexico at approximately 9,500 ft (2,900 m). The award for the Stones development follows a technology qualification program.

The subsea processing systems scope of supply includes a dual pump station with two 3-megawatt single-phase pumps and two subsea control modules, a topside power and control module, a barrier-fluid hydraulic power unit with associated spares as well as installation and maintenance tools. Manufacturing and testing will take place at OneSubsea’s processing center of excellence facility in Horsoy, Norway.

“Based on OneSubsea’s field-proven boosting technology, this is another innovative step forward for our subsea pumping systems,” said Jack Moore, Chairman and Chief Executive Officer of Cameron. “This boosting technology will be key for enhancing recovery and increasing production from the ultra-deepwater environment in the Lower Tertiary region of the Gulf of Mexico.”

The system will be tied back to the Stones FPSO, and delivery is expected in early 2018. Stones is located 200 miles southwest of New Orleans, La.