Geothermal well control training can benefit by learning from real-world oil and gas incidents

Analyzing human, technical and operational factors in past events will help geothermal industry address risks, build skilled workforce

By Bhavesh Ranka, Cudd Well Control, and Toney Deer, Well Control School

The expanding geothermal industry, while distinct from oil and gas, faces similar well control challenges. The high temperatures and pressures involved in geothermal drilling require a focused approach to well integrity and well control. To ensure an informed, skilled and safety-conscious workforce, training programs must incorporate lessons learned from past well control incidents.

This article provides a technical framework for leveraging these incidents to develop effective well control training that enhances safety and efficiency.

Role of incident analysis

Past well control incidents in both industries serve as invaluable learning opportunities. A post-incident analysis is designed to understand the cause and identify the combination of technical, operational and human factors that led to the event. This information is then used to develop targeted training.

Geothermal drilling presents distinct technical challenges. Reservoirs often contain fractured rock and unpredictable fluid pathways, complicating operations. Extreme heat degrades drilling fluids, which makes it difficult to maintain wellbore stability and manage hydrostatic pressure. These conditions can lead to well control incidents.

Effective training must prepare crews for these situations by incorporating a curriculum to cover advanced geology, specialized drilling fluids and proper well construction practices. While knowledge from other energy industries provides a foundation, it is not sufficient. Geothermal wells have unique characteristics that demand specific training.

Geothermal drilling has multiple operational challenges, including complex well trajectories, extreme heat and pressure, and significant fluid losses. These factors complicate the detection of kicks, shut-in procedures and kill operations. High temperatures, in particular, reduce the density difference between the drilling fluid and an influx, which can mask standard kick indicators. The frequency of well control incidents due to these challenges highlights the need for specialized procedures tailored to geothermal operations.

Human factors, including training gaps, communication breakdowns and procedural deviations, play a significant role in operational safety. Insufficient or irrelevant training, coupled with a lack of experience, often results in incorrect actions.

Additionally, poor communication can delay decision making during a well control event. When personnel fail to adhere to established procedures, it highlights the need for a culture of understanding and strict compliance, reinforced through continuous competency assessments. Analyzing near-misses is also essential, as it helps identify weaknesses and address them proactively.

Integrating incident data

Well control training is most effective when it is built on lessons from real-world incidents and near-misses. Training should use case studies of actual well control events from both geothermal and oil and gas. Each case study must analyze the technical, operational and human factors that caused the incident. Trainees are then challenged to develop better procedures to prevent a similar event. These case studies should cover scenarios like kicks caused by lost circulation, unexpected casing pressure, wellbore breathing, and surge and swab pressures.

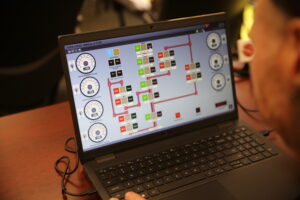

Realistic simulators are also required to prepare crews for high-risk situations. The simulators must be programmed with data from actual incidents to accurately replicate geothermal conditions, such as steam kicks. This allows trainees to experience the event and test different responses in a controlled environment.

A post-simulation review connects the trainee’s performance back to the lessons from the original incident. It must be understood that bullheading and quenching are not the same methods. Training must connect theory to practical skills for the specific challenges. Hands-on exercises for choke and pump operations should be based on the conditions that led to past failures. This approach, rooted in incident data, encourages proactive risk assessment and prevention.

Immersive learning

The effectiveness of well control training can be greatly enhanced through the adoption of advanced methodologies and technologies that leverage incident data. Dynamic models and real-time data integration within simulators provide an unmatched level of realism. Advanced simulators will incorporate real-time drilling parameters, geological data and fluid properties to create a dynamic representation of wellbore conditions.

This allows trainees to make decisions based on evolving data, much like they would in a real-world drilling operation. By doing so, they can refine their ability to react under pressure and manage complex well control events, particularly those involving unexpected pressure changes.

The integration of immersive learning with detailed 3D modeling further enhances the training environment. Trainees can be immersed in highly realistic scenarios, interacting with equipment through physical feedback, observing wellbore dynamics and practicing procedures in a detailed, hands-on setting.

Advanced simulators can enable repeated practice of complex procedures, improve spatial awareness and significantly boost mental retention and reaction time – without the risks associated with live well operations. This capability is especially crucial in visualizing pressure behaviors and equipment responses during incident scenarios.

The rapid expansion of the geothermal industry highlights the urgent need for consistent well control planning, training and certification standards, informed by incident analysis. While the oil and gas industry has well-established frameworks (e.g., IADC WellSharp, IWCF), the geothermal sector is developing tailored standards to address its unique technical challenges. These standards will include specific curricula for geothermal kick characteristics; high-pressure, high-temperature equipment limitations; and specialized kill procedures, all based on a comprehensive understanding of past pressure control incidents. Establishing these standards will ensure a baseline level of competency across the industry, facilitate workforce mobility and promote a unified approach to safety and knowledge.

A robust safety culture

Technical training must be paired with a strong safety culture. This culture requires that every incident, regardless of severity, is documented and analyzed. The knowledge gained from these analyses, particularly regarding pressure control, must be shared across all teams. This open communication ensures best practices and lessons learned are spread throughout the organization.

A culture of safety drives continuous improvement. Every phase of an operation becomes an opportunity to refine procedures, enhance training and strengthen safety protocols. By analyzing past events, the industry reduces operational risk and improves well control. This process builds a skilled and resilient workforce capable of developing this vital energy resource.

Well control incidents from traditional oil and gas operations provide valuable lessons that can be applied to geothermal operations. With the frequency of blowouts in the oil and gas sector, these real-world experiences offer critical insights for improving safety measures. By incorporating these lessons learned, geothermal operations can enhance incident prevention and foster a culture centered around safety.

Conclusion

The transition to a sustainable energy future depends heavily on the responsible development of geothermal resources. By thoroughly analyzing past well control incidents, particularly those involving pressure control anomalies, and integrating these insights into simulation-driven training programs, the geothermal industry can proactively address risks and build a highly skilled workforce. Adopting advanced training methods and establishing consistent industrywide standards are not just beneficial, they are essential for ensuring the future of geothermal energy through improved well control safety and operational excellence. DC

This article is based on a presentation at the 2025 IADC Well Control Conference of the Americas, 19-20 August, New Orleans, La.