Advanced robotics enable revolution on the rig floor

Land rig automation takes big step forward with installation of modular, industrial robotic arms on Precision and H&P rigs

By Stephen Whitfield, Senior Editor

A continuous drive to remove people from the red zone of the drill floor has succeeded to varying degrees over the past few decades. Although some rig floor processes remain manual because humans are tough to replace, automation and robotics are being integrated to eliminate much of the variability associated with human operators on the rig, moving those humans to other roles farther from harm’s way.

NOV’s ATOM RTX, launched in 2022, is one such system. Centered around a series of robotic arms, it serves as the mechanization link between process automation and the execution of drill floor tasks, such as tripping in and out, tailing pipe on the rig floor and at height on the racking board. While some mechanized solutions have existed before, it is the first robotic arm system developed for a rig. The broad range of tasks it can handle in place of a human is proving useful for drilling contractors looking to scale their automation efforts.

“The industry conversation has always been, is there a better way to work around the red zone? Is there a better way to handle heavy equipment on the rig?” said Graham Dey, VP of Product Management at NOV’s Rig Technologies. “We have technology that can help. It has been in use in other industries for some time, but we’ve made it a possibility to use it within our operating environments. As visibility and comfort with its use has grown, you get alignment with industry stakeholders. They’re seeing it work, and they have enough confidence that they can deploy the technology, improving safety for their crews and the efficiency of their operations.”

The system has seen positive results in the field, with an initial deployment last year on a Precision Drilling land rig in the Montney Shale in Canada. The project saw NOV’s robotic arms integrated with Precision’s AlphaAutomation software application, resulting in the AlphaARMS offering.

The AlphaARMS system enabled 95% of rig floor activities to be automated and derisked the well by eliminating over 70,000 manual touchpoints.

“There are a lot of challenges when we look at robotics. You’re looking at connections, tripping in and tripping out, running casing. How can we take the workflow of what our people have perfected over the last decades and get the robotics to do the same thing?” said Rob Houston, VP of US Drilling at Precision Drilling. “But we really wanted to be in this space, and our customer in Canada wanted to be in this space. A system like this gives us so many additional data points that we didn’t have, and that’s allowing us to drive efficiencies and give us improved consistency on the rig floor and throughout the well construction process.”

The NOV robotics system is also the key component of H&P’s FlexRobotics system, which was recently installed on FlexRig 618. Scheduled to be delivered to the Permian in September for a planned spud by the end of the month, it is the first rig in the company’s fleet to commercially deploy with a FlexRobotics system. It will also be the first rig in the Lower 48 to operate with an industrial robotics package, according to H&P.

The company says it sees the package as a means to remove people from the red zone while maintaining or improving the same level of operational efficiency. The company hopes that demonstrated success in the field will drive further operator interest and adoption.

“With this rig, we aim to demonstrate that we can drill wells as efficiently as our non-robotic rigs,” said Todd Fox, Director – Product Management at H&P. “At a minimum, there should be no reduction in performance while delivering more consistent execution – that, by itself, is a benefit. Moreover, we seek to scale this technology. Economics and optimization will improve with scale and, to scale the technology, we will need to deliver predictable and efficient performance.”

Building the arms

While there are automated tubular handling systems in commercial use today on both land and offshore rigs, many of these systems were custom-designed to manage rig floor tasks by re-imagining those workflows without humans. In many cases, this leads to requisite changes in rig floor layout that make it difficult for the company to go back and re-introduce human workflows when needed. This makes it harder for some of these systems to gain traction, as it requires significant commitment to the new technology and locks the company into a rig that can use only automated pipe handling and rig floor equipment.

On the other hand, utilizing robotics to replicate human tasks allows workflows to remain largely the same. This is a significant advantage for implementation, as the existing workflows for most rigs are well understood and have been refined with conventional equipment.

“When we’re developing tools, and robotics specifically, they need to be tools that are useful to the drill crew,” said Brandt Lanzet, Product Line Manager – Automation and Robotics at NOV. “This system is not something that’s replacing a human. It’s something that can do as many of the jobs as a human could do and is as useful as a human could be within the red zone, but we really see it as something that can help bolster their working environment and free them up for other tasks.”

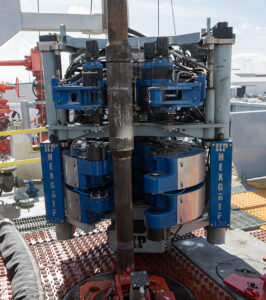

NOV’s land robotics system consists of two six-axis robotic arms (referred to as “L1” and “L2”) mounted on tracks on the rig floor, along with a six-axis arm in the monkey board (“U1”). U1 carries out all derrickhand pipe handling tasks, while L1 handles all tailing and stabbing. L2 takes care of doping, mud containment and stabbing guide tasks.

The arms, which form the base of the system, were sourced from a third-party manufacturer that specializes in industrial robotic systems. To customize the arms for oilfield applications, NOV developed and attached various end effectors, or peripheral devices connected to the “wrist” of the robot. They allow the arms to interact with their environment – effectively serving as the “hands.” These end effectors were specifically designed to mimic various activities on a drilling rig.

“There’s a lot of functionality that’s intrinsic in this robotic system,” Mr Dey said. “Tailing the pipe at the drill floor is an intrinsic part of the delivery. Integrating the mud bucket function, that’s an intrinsic part of the delivery. We also configured the system to carry out the doping and stabbing, which is also intrinsic. But the other thing about this functionality is that it makes this system configurable. For our project with Precision, they wanted us to add a tail casing, so we designed something that allowed us to do that. It’s like an iPhone, where there are a lot of apps that serve as that intrinsic functionality within the device and make the device customizable.”

With the robotic arms and end effectors combined, these machines then integrate into the rig’s process control system and automation application, eliminating the need for the driller to manually operate the robotics. The driller supervises the operations and initiates processes for the robotics to execute. The machines’ environments are mapped out with preplanned paths for each sequence of handling drilling tubulars and casing.

Additionally, the system constantly monitors stump height and hole center, while a gate safety system shuts down all robotic movement if triggered by any humans entering the hazard area.

“Our robots aren’t physically picking up any pipe, so you don’t need any beefy pieces of equipment that would handle all that load,” Mr Lanzet said. “We use the existing rig equipment – the elevators and the drawworks – to lift the pipe, and we just use the robots as guiding mechanisms. This is exactly how it’s done manually where the derrickman and the forehands are tailing pipe. We’re doing the same things with the robots. Because we’re not actually lifting the equipment, we’re able to keep the footprint of this system pretty small and design that modularity.”

While the package can operate on offshore rigs, it was originally developed to replicate the workflow of a land rig. For a typical North American land drilling operation, batch drilling multiple wells on a pad is common practice due to associated time and cost efficiencies. Because of this, the workers who handle drill pipe and equipment during a connection – usually one derrickhand and two floorhands – are regularly multitasking on top of making the connection. Associated tasks may include strapping casing, taking mud or cuttings samples, and equipment maintenance. Each connection that needs to be made interrupts these other tasks when crews must report to the rig floor.

With the ATOM RTX package working with an automation system, these crew members are no longer required to be present on the rig floor for these high-frequency tasks at connections. This allows them to focus on whatever additional tasks they may be doing, without interruptions. This can lead to improvements in equipment health, resulting in more productive time and less downtime on the rig.

Additionally, with the robotics package eliminating the need for manual connections, workers will be more available to perform other preparatory tasks required before new operations, which can reduce flat time.

Mr Dey emphasized the importance of the robotics in helping to improve rig floor workflows: “For us, the thing that we’re trying to convey with this system is that the drill crews make the operation work. You have to respect that. The crews are our ultimate customer. If we make technology that they love and makes their lives better, they’re going to use it.”

The robotics package is either currently available, or contracted for delivery, on four land rigs globally. Offshore, the package is either currently running or contracted for delivery on one jackup and nine drillships.

The tubular handling function isn’t utilized offshore, however. Instead, the arms are attached with end effectors for doping and mud containment, with several more functionalities in various stages of development.

“Offshore rigs already have a lot of mechanization equipment that’s capable of tasks like guiding tubulars, as well as automation systems that automate the process,” Mr Lanzet said. “However, there are still people coming into the red zone for various tasks around doping or the dog collar, and this system is well suited for those tasks. There are several other considerations within an offshore red zone where people are still moving around that we’re developing tools for the robots to do.”

Precision’s implementation in Canada

Precision’s involvement with the robotics package grew out of everyone being at the right place at the right time, according to Mr Houston. Discussions around deploying the technology in Canada’s Montney Shale began in 2021, shortly after he assumed the role of Precision’s Director of Rig Technology.

In his first conversations with NOV, he recalled, he was attracted to the modular design of the robotic arms: “Our industry is not in a spot to build new rigs, so a modular approach made sense.”

Trials run on NOV’s test rig in Navasota, Texas, indicated that the arm system could remain modular but also be sufficiently integrated into the rig design to minimize impact on rig moves, adding roughly only two hours to rig-up and rig-down time. Additionally, the system could be moved to other rigs within the fleet with some retrofitting, if needed. And if a robotic arm is down, all tubular handling activities could still be performed manually as Precision still had a Tier 1 drilling rig asset to utilize. This provided an additional layer of redundancy.

“If I’m putting a capital investment into a rig and the contract changes, I have the ability to move that equipment to another rig more easily than a rig built around robotics,” Mr Houston said. “If this was something that was bolted into place, that would’ve been a lot of cost and risk. Moreover, we didn’t want to have our decision-making capability taken away. If the customer wants to change the string of drill pipe, you need a system that allows you to stay nimble enough where that won’t cause you to shut down your operation.”

Both Precision and the operator also saw value in safety gains, with the robotics helping to de-risk the drilling process. “We want to enable closed-loop drilling,” Mr Houston said. “Automation can handle everything downhole, but we still have all these variables happening at the rig floor. The functionality piece with this is so important; we wanted a system that could replicate today’s workflow and not reinvent the wheel. Let’s just have the robotics do what people do.”

The system was first installed on the Precision rig in early 2023, during testing prior to deployment. Several hurdles were identified and addressed.

For example, with the current rig design and the layout of the hardware, Precision discovered an electrical interference issue. This issue would cause faults with robotics while other pieces of equipment on the rig floor were in use. This was due to differences in the layout between NOV’s test rig and Precision’s rig – primarily the proximity of the arms to the local equipment room. To address this, a harmonic filtering system was installed to reduce the electrical noise around the rig floor.

Another hurdle was identified around the need for more standardization with drill string design and use. If the operator wanted to change its string design or adjust the quantity of heavyweight drill pipe in the string based on the well trajectory, such changes could no longer be done on the fly. Additional pre-planning would be required to map out how the robotics would rack and handle the tubulars. As a result of this concern, Precision built in flexibility to run multiple drill string designs with little to no time required to make the changes.

It was also found that extreme weather led to slower movement of equipment operated by hydraulics, such as elevators and the iron roughneck. The robotic arms are electric, driven by servo motors, and they slowed down in cold weather (below -15˚F). Utilizing different greases in colder temperatures helped to mitigate this issue.

The AlphaAutomation software was also updated to include a “cold weather mode” that enacts continuous small movements to keep the grease less viscous. If needed, the rig also has electric heating jackets that could be used to keep the arms warm.

By the end of commissioning, the robotics support team had found new and creative ways to improve not only the new equipment capabilities in cold weather but also existing equipment.

The rig crew also had a learning curve around the fluency and integration of movement with the robotic arms. For safety reasons, all robotic sequences had to be initiated by the driller and confirmed before moving on to the following sequence within a process. All drillers began by initiating and supervising one sequence at a time to completion. Once they were more familiar with the movement of the machines and the time required for each sequence, some sequences could be overlapped utilizing multi-machine control.

For example, once proficient, the driller could begin moving the blocks up and initiate the derrickman robot sequence to start grabbing a stand from the fingerboard while the rig floor robotics finish their current tasks. As connection times began to vary by driller, it became clear that the individual driller’s proficiency with the system was vital in terms of achieving time savings through the robotics. These learnings were captured, shared with development teams and then programmed into sequences for continuous efficiencies.

Mr Houston noted that previous training that Precision and the operator had undertaken with the system at NOV’s training rig, along with virtual simulator training, helped significantly with minimizing the rig crew’s learning curve. “We brought our customer with us to learn the same system with the drillers. That really helped give everyone the flexibility that comes with the operator understanding our capabilities and the driller understanding what the operator needs.”

Since going live in Q1 2024, the package has “exceeded expectations” in the field, Mr Houston said. Precision had initially planned to automate just 80% of rig floor activities, meaning that 20% of the time the rig was operating, humans would be physically manning the equipment on the rig floor.

However, the company has so far already automated 95% of rig floor activities, beating expectations. This substantially reduced the exposure for those crew members primarily responsible for connections.

When measured against a conventional sister rig with the same specs as the robotics rig, the workers on the robotics rig spent approximately 2.7 fewer days on the rig floor over each two-week period while robotics were utilized for repetitive manual rig floor tasks. This represented a 36% decrease in cumulative hours spent on the floor – this was time that could be allocated to rig maintenance and a focus on flat time reduction.

The robotics package has also driven efficiency improvements. Precision saw a 36% improvement in consistency for tripping in and a 21% more consistent trip-out rate for the rig with the robotics package versus a conventional sister rig. Consistency, in this case, was measured by the standard deviation of stands tripped per hour.

Mr Houston said Precision’s main focus with the system now is scaling it to other rigs – with additional operators. Conversations are ongoing to align on future projects.

“I think we all own a part in scaling this,” Mr Houston said. “As a drilling contractor, we can make strategic decisions to standardize this environment on the rig floor, which should make scaling easier because we could have a lot of very similar rig styles that would have the same functionality. The customer has to be a partner giving us reasons why this will succeed, and we need to have support services such as casing companies work with us so we can always be prepared for the next steps. A lot of ecosystems have to align to make this happen.”

H&P’s implementation on a Permian rig

NOV also provided the ATOM arms for H&P’s FlexRobotics package, which was recently installed on FlexRig 618 in Houston before a planned move to the Permian Basin in September.

This installation does not deviate significantly from NOV’s original design of the robotic arms – one arm is located on the rig floor in front of the drawworks, another is on the floor near the driller’s cabin, and the third is on the monkey board to manage pipe handling tasks.

NOV also installed its stump height detection and red zone management systems on the rig floor, and updated its code for the robotic arms in order to enable a smooth integration with H&P’s automation application.

“The NOV code works in conjunction with the H&P code. In our case, we’re uniquely positioned in that we develop and implement all of the control code on the rig, so we’re able to make everything work ourselves without relying solely on an OEM,” Mr Fox said. “When a handoff occurs to the robotic arm, NOV’s operating code controls the robotic arm, and when the robotic arm hands off to our equipment, our code continues the operation. There are a lot of operations happening at the same time. The drawworks are moving, bales are moving, slips are setting.”

H&P first began talks with NOV and an operator in 2022 about the robotics package, with the driller placing its initial order for the system in September of that year. In May 2024, NOV installed a prototype of the robotic arms on H&P R&D FlexRig 918, located at the driller’s facility in Tulsa, Okla., to begin initial testing. This testing was fairly straightforward – essentially making sure that the system worked as expected, achieved the desired KPIs, that the rig crew’s learning curve was not too steep, and ensuring integration with the rig’s operating code and equipment zone management.

“When we worked on the design, we wanted to minimize the additional workload for the driller. We had evaluated the technology for a couple of years on our R&D rig before we installed it on FlexRig 618, so we were able to work with our drillers and adapt their feedback into the system. The handoffs are similar to the handoffs on a non-robotic rig, only they’re handing pipe off to a robotic arm rather than a member of their crew,” Mr Fox said.

He also noted various nuances within the controls of the robotic arms and the exact placement of the arms. “We had to make sure that equipment collisions were prevented, and that was a long process because you have different equipment moving in a 3D space at different times.”

The initial deployment in the Permian will focus on ensuring tripping and connections can be operated with an efficiency as close to human performance as possible – Mr Fox said H&P has set a KPI goal of a 5% or less difference between the tripping and connection speed of the robotics package and that of a rig crew handling the operation. “Right now, our focus is on achieving the minimum viable product, and then after that we will focus on improving operational efficiency.”

Even though the robotics package will eliminate some rig crew functions with pipe handling, Mr Fox emphasized that H&P still sees the crew as a vital part of operations.

“This system absolutely will not replace the crew,” he said. “Our crews will continue to play a key role in planning and executing other operations. Eventually we may see the skillsets and primary job functions evolve. We see the robotic arms as technology to give time back to our crews so that other operations can be executed even more efficiently than today.” DC