Continuous inclination, azimuth measurement optimizes RSS control

Continuous automatic hold inclination, azimuth capabilities enhance automated steering, enable continuous directional measurement

By Junichi Sugiura, Peter Hornblower, Richard Hawkins, Ross Lowdon, Aboyi Olokpo and Cesar Figueredo, Schlumberger

When they were introduced in the mid-1990s, rotary steerable systems (RSS) represented a step-change in directional drilling. Over the years, continued advances have expanded the operating window of RSS. As the drilling industry moves toward greater automation, RSS has been further enhanced with the capability for automated steering in tangent sections, including the vertical and lateral sections.

The new downhole steering and measurement algorithms are taking RSS to the next level in steering capability and downhole survey methods. Field tests in US shale plays shown improved efficiency.

The continuous automatic hold inclination and azimuth (HIA) capability reduces human-machine interaction by using a continuous real-time measurement of inclination and azimuth to optimize control of the trajectory and minimize wellbore tortuosity. This reduces reliance on a previously computed survey model and the need to stop drilling to take individual confirmation (static) surveys with conventional measurement-while-drilling (MWD) tools.

The automated steering mode is enabled by downhole trajectory-control algorithms that make frequent, small adjustments to the RSS steering parameters, comparing near-bit continuous survey data with the target attitude. The new survey method, using near-bit sensors, improves the inclination and azimuth measurement in near-vertical angles, enhancing the automated vertical drilling feature and providing a more accurate kickoff. The continuous measurements allow the trajectory-following algorithm of the RSS to drill lateral sections more precisely.

The advanced HIA system has been implemented in two Schlumberger PowerDrive RSS tools, the PowerDrive Archer hybrid RSS and the PowerDrive Orbit RSS. The first features dogleg capability up to 17° to 20° per 100 ft, providing control in unconsolidated formations and pushes through hard stingers. By establishing deep kickoff points, the tool reduces inclination in unstable formations and footage to the reservoir.

The PowerDrive Orbit RSS can perform multiple functions in one run and achieve higher revolutions per minute (RPM), especially in situations of dogleg severity (DLS). A six-axis component uses an extended-range sensor to facilitate enhanced HIA for better automatic attitude control to drill more deviated wells. In straight sections, the sensor can make an automatic adjustment in a fast-response, closed-loop system to keep a specific inclination and azimuth. The system also reduces the number of downlinks and static confirmation surveys needed for downhole communication.

Accuracy and reliability

In North America, typical shale wells are drilled with a build rate of 8° to 12° per 100 ft to land horizontally with at least a 3,000- to 5,000-ft lateral section. As operators extend horizontal sections, they require RSS solutions that provide greater accuracy and reliability and can drill higher-degree doglegs.

Development of the automatic HIA software provides the ability to compare actual inclination and azimuth against the target inclination and azimuth to make frequent adjustments and minimize errors. This can lead to significant time and cost savings in drilling the vertical and lateral sections.

The use of automated vertical drilling algorithms in RSS is not uncommon anymore and typically involves setting the target gravity tool face (GTF) of the RSS to the low side of the borehole. A relatively low DLS is required to maintain the vertical direction of the hole. The accuracy of the near-vertical GTF is highly dependent on the accuracy of transverse acceleration measurements, which can be degraded by sensor aging, residual calibration errors and limited tolerances of the tool assembly, conditions that can adversely impact survey calculations.

The new survey measurement method overcomes these limitations by dynamically calibrating sensors downhole to improve the vertical drilling performance of the RSS with comprehensive six-axis continuous inclination and azimuth measurements that facilitate automation HIA capability. Improved vertical drilling reduces tortuosity in the top hole, which is important in constructing the subsequent sections of the well. Computing an accurate GTF at the RSS, along with predictable steering ability of the RSS, provides a straighter wellbore. Improved continuous inclination and azimuth near the vertical section also gives the directional driller confidence that the vertical section is truly vertical.

Efficiency improved

More accurate measurements also reduce the number of MWD static surveys required in the vertical section. Further, receiving accurate continuous azimuth measurements close to the bit eliminates the need to take extra surveys around the kickoff points. The directional driller can switch to gravity tool face mode at inclinations less than 3°, making it easier to determine the steering direction.

For the lateral section, documentation of conventional automated inclination hold (IH) technology using RSS has revealed a number of technical challenges in achieving closed-loop azimuth control downhole. In a conventional scenario, azimuth sensors, such as magnetometers, are placed 20 to 30 ft or more away from the bit. The continuous azimuth measurement is noisier than the continuous inclination measurement and becomes inaccurate and unstable in the north/south direction, which is how the lateral sections in most wells in certain shale plays are planned because of lease requirements and the direction of formation stresses.

With the capability of six-axis continuous inclination and azimuth measurements, the HIA feature offers a key advantage over conventional MWD tools by providing accurate and precise measurement of continuous azimuth close to the bit in the north/south lateral. In a high-dogleg well, for example, the RSS can drill the entire lateral section in automated steering mode, or HIA, even when the well is trending close to the magnetic north or south. This reduces the human-machine interface, minimizes tortuosity and improves the true vertical depth (TVD) definition.

With PowerDrive Orbit and PowerDrive Archer RSS, the magnetometers can be located about 8 ft from the bit. The RSS continually computes the near-bit inclination and near-bit azimuth while drilling ahead. The downhole controller makes frequent inclination and azimuth adjustments in a closed-loop manner to track the target inclination and azimuth. This allows the HIA feature to achieve closed-loop control of both inclination and azimuth in the north/south direction and steer the lateral and tangent sections more efficiently.

High-dogleg RSS

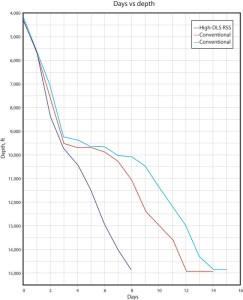

The effectiveness of the new downhole steering and measurement algorithms has been verified in hardware-in-the-loop simulators and in the field. In field tests in multiple US land wells, the HIA software demonstrated greater efficiency and reliability compared with the conventional method of taking static MWD attitude measurements while drilling. In Texas’ Eagle Ford play, the PowerDrive Archer RSS was optimized with the downhole steering automation and the new survey measurement features, in both the vertical and lateral sections, in two pad wells. The high-dogleg system drilled more than 10,750 ft, including the 5,000-ft vertical section and 4,500 ft of lateral, in the due magnetic north direction.

In the first well, the automated vertical drilling mode drilled 5,000 ft in a 3D plot with a north-south/east-west deviation within a target area of 0.5 ft-by-0.5 ft, keeping the well inclination less than 0.2°. The near-bit continuous inclinations from the RSS matched the MWD static survey inclinations taken every 100 ft.

A second HIA mode was used to drill the 4,500-ft lateral section of the same well. The continuous inclinations using both the MWD static survey points and the HIA technology were accurate. However, the RSS continuous inclination measurement was made 8 ft from the bit, while the MWD continuous inclination was taken approximately 50 ft from the bit. The RSS continuous azimuth was smooth, with no issues observed in several crossings of the due magnetic north azimuth. The MWD continuous azimuth was much noisier along the entire lateral section, which can compromise the feedback signal to the closed-loop azimuth controller. The RSS remained in automated HIA mode for the entire lateral section.

In the second Eagle Ford well, the HIA feature was again deployed in the due magnetic north direction. The RSS HIA drilled the vertical, high-dogleg curve and lateral sections in one run. The RSS continuous azimuth was smooth, with no issues observed in several crossings of the due magnetic north inclination. In the lateral section, the HIA precisely placed the well, and the RSS drilled more than 10,750 ft in automated steering mode, saving four days of rig time – about 30% compared with previous non-dogleg runs using the best steerable motor performance on the pad.

Directional wells have pushed the limits of conventional technology in drilling complex vertical and lateral well sections. RSS systems enhanced with a combination of downhole HIA steering automation and a new rotating survey measurement method are giving operators greater confidence to drill ahead.

PowerDrive, PowerDrive Archer and PowerDrive Orbit are marks of Schlumberger.

This article is based on two papers presented at the 2013 SPE Annual Technical Conference and Exhibition, 30 September – 2 October in New Orleans, Louisiana.