D&C Tech Digest

Hardbanding saves damaged drillstring in Russia

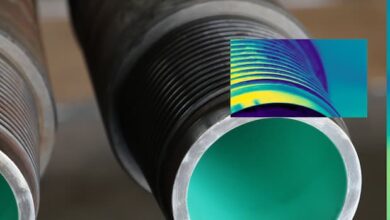

When applying new hardbanding on top of worn and cracked hardbanding, there is a risk of incurring additional durability problems.

Recently, a Russian offshore drilling contractor’s drill pipe showed signs of wear and traverse cracking with a titanium hardbanding product. Duraband non-cracking (NC) hardband was chosen for re-application, and Hardbanding Solutions Europe was asked to oversee the work of removal, repair of the tool joints and application of Postalloy Duraband NC. The drilling contractor decided to remove the damaged hardbanding. A magnetic particle inspection (MPI) was then used to ensure that all cracks were removed. Following recommended preheat temperatures, a Postle product, HBBU, was applied to recover the original tool joint outside diameter dimensions. Postalloy HBBU is a low-alloy hardbanding wire that matches the physical properties of the tool joint. A further machining procedure was conducted to recover exact OD dimensions.

MPI was used again to ensure that new cracks were not initiated. Duraband NC was then applied over the Postalloy HBBU. Slow cooling procedures were implemented to ensure that heat-affected zone hardness values did not exceed 40 Rockwell C. The finished hardbanding was again subjected to MPI to ensure that cracks did not develop.

NCS Multistage system enables controlled refrac

NCS Multistage has announced the successful refrac of a 25-stage well that had originally been completed utilizing the company’s Multistage Unlimited coiled-tubing frac system and MultiCycle frac sleeves, which gave the operator the ability to manage stage-by-stage formation access over the life of the well. After evaluating production, the operator wished to increase stimulated reservoir volume by placing additional proppant in all stages, using a different fluid system and higher pump rates than used in the original completion.

The refrac began by closing all of the sleeves and verifying wellbore pressure integrity. Then, using the NCS Shift-Frac-Close sequence, all 25 stages were individually refractured. At each stage, the MultiCycle sleeve was opened for the frac and then immediately closed at the end of pumping. When the stimulation was complete, the full-drift wellbore was again pressure-tested, all sleeves were re-opened, and the well was turned over to production. The entire refrac took approximately 36 operating hours, and wellbore pressure and formation access were controlled throughout the operation.

FracIQ Limited Entry Perforating System applied in 1,000-plus stages

GEODynamics’ Engineered Perforating Solutions Division has completed extensive field testing of the latest addition to its family of plug and perf technology based products. The FracIQ Limited Entry Perforating System has been applied in more than 1,000 frac stages since field testing commenced in April 2016.

The patent-pending FracIQ Perforating System is designed to generate constant and consistent perforating entry holes and penetration depths in wells. The FracIQ System is available in 0.30-in., 0.35-in. and 0.40-in. hole sizes.

Halliburton Installs 1,000 multilateral junctions

Halliburton recently announced the installation of 1,000 multilateral junctions. The company’s global multilateral technology group has installed these junctions, which join laterals to the main wellbore, in more than 840 wells worldwide since 1993, with an overall success rate of 98%, the highest success rate in the industry, according to Halliburton.

TGS, Schlumberger commence US GOM surveys

TGS and Schlumberger recently announced commencement of the Dual Coil Shooting multivessel full-azimuth acquisition Revolution XII and XIII surveys in the US Gulf of Mexico. The surveys will cover approximately 7,150 sq-km, or 306 blocks in the Green Canyon, Atwater Valley and Ewing Bank protraction areas of the Central Gulf of Mexico. The Revolution XIl and XIII surveys will be acquired using the Schlumberger WesternGeco Q-Marine point-receiver marine seismic system combined with the proprietary multivessel, Dual Coil Shooting acquisition technique, which will provide broadband, long-offset, full-azimuth data.

This combination will improve illumination and imaging of the sub-salt and other complex geologic features in this highly active region. Acquisition is expected to complete in late Q1 2017 with final processed data available in early 2018.

These Revolution Dual Coil Shooting full-azimuth surveys will record offsets of more than 14 km for imaging below the salt in the deepwater GOM. In this latest generation of Revolution surveys, autonomous marine vehicles (AMV) are being deployed. These AMVs will simultaneously acquire ultra-long offsets of more than 20 km, which benefit full waveform inversion in the accurate velocity model building over such complex subsalt areas. “The Revolution XII and XIII surveys benefit from the latest advances in seismic technology and will provide the E&P industry with critical information to support exploration and drilling activity in (the) region,” TGS CEO Kristian Johansen said.