GE: Shale water challenges call for flexible solutions

By Katherine Scott, associate editor

When it comes to unconventionals, the focus over the past several years has been around water – how to manage it, how to treat it, how to reduce the necessity to transport it to and from the well site and how to increase its reuse have all developed into significant issues for the industry. “It’s usually one of the first concerns that you hear,” John Westerheide, strategic marketing leader – unconventional resources, GE Oil & Gas, said at the company’s 2013 annual meeting on 29 January in Florence, Italy. One challenge to these water issues, however, is that not one solution can be applied to all shale plays because different regions require different treatments.

For instance, Mr Westerheide said, in Western Oklahoma, the discussion of water management is usually about water scarcity, whereas the Marcellus lacks the proper geology for saltwater disposal wells, therefore operations have to truck water in and out or take it to treatment plants, he explained.

The key, then, is creating flexible solutions, he said. “A customer doesn’t always need to be able to fill up a water bottle off the backside of our treatment and be drinking distilled water. Sometimes you may just need to get it treated to where you’re going to stick it down a salt-water disposal well. In other cases, you might want to use it on the next well, and you have a specific water quality that you’re trying to hit. More importantly, it’s figuring out how to treat the water economically.”

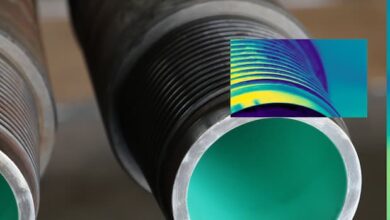

Among GE’s water treatment and management technologies is the mobile thermal evaporator, which uses heat to distill water and concentrate brine. It is mounted on a single trailer so it can reach remote drilling sites. “We took our stable system and put it on a trailer, and now they can drive between plays, they can drive between wells to reach the customer where they’re at and take care of the challenge and the solution,” Mr Westerheide said.

The tool, launched in September 2010, was designed to help natural gas producers recycle untreated water that result from the hydraulic fracturing process at the well site. It has been used in unconventional gas and frac water applications in North America. For most of 2012, it was deployed in the Permian Basin in West Texas, where it was used to treat produced water from shale oil and shale gas operations.

In another project, GE is taking produced water and turning it into a commercial product – road salt. In a recent pilot project, the company took produced water from the Marcellus, analyzed it, evaporated and crystallized it. Pennsylvania’s Department of Transportation certified the product as road salt they would buy, Mr Westerheide said. “Imagine you’re a producer in the Marcellus shale, and you’ve got a whole bunch of water and water is a problem for you. What do you do with it? Now I can not only recover my water, so I need less of it and I’m being a better steward of my resources, but I have a by-product that I can sell to the state of Pennsylvania. That’s a fantastic story, and those are the types of things that we’re looking to do.”