High-strength, thin-wall, all-steel drill pipe may provide solution for ultra-extended-reach wells

By Lou Elliott and Vincent Buchoud, VAM Drilling; Tony Krepp, K & M Technology

In planning for ultra-extended-reach (uER) wells, projected torque & drag (T&D) loads exceed the capabilities of existing high-strength drill pipe. As operators continue to evaluate uER well options, they have been forced to consider using non-steel drill pipe materials (such as aluminum, titanium, composite or other) for reduced surface loads. While these materials have been used for some time in a variety of applications, many drilling engineers are reluctant to pursue complicated and high-value developments with what they perceive as lesser known or less understood technologies.

An alternative approach (and/or complementary approach) is to use new ultra-high-strength material, which will bridge the gap between existing steel grades and alternative solutions. The significantly improved strength-to-weight ratio performance properties of this material allows fit-for-purpose drill pipe to be designed for this specific application.

Following the successful development of 165 ksi material (VM-165 grade), one operator has selected high-strength thin-wall 165 ksi drill pipe as the best solution for their uER well development. This article will discuss the key performance drivers that enabled the operator to select this all-steel alternative and the methodology used for specifying the final acceptance criteria of this material.

BACKGROUND

Due to the operator’s environmental and commercial considerations, this new shallow-water field (6 m/20 ft) will take advantage of existing infrastructure in order to be developed. The projected wells are significantly beyond current industry experience so are considered uER wells.

Detailed planning has identified the necessary technical solutions for drilling, casing and completions operations. New technology solutions need to be developed for all phases of the wells. Of specific interest here is the rig’s equipment and advanced drill pipe technology.

TECHNICAL DRIVERS

From a modeling perspective, this article will focus on the 10 5/8-in. hole section, from approximately 36,760 ft to 48,000 ft (11,200 m to 14,630 m) MD. The drill pipe design and selection is critical for wells of this magnitude. Detailed planning shows that non-conventional solutions are necessary for the final hole sections to TD.

Both all-steel and alternative-material drillstring materials were considered. Use of existing drill pipe involves surface torque loads that cannot be managed without developing new top drive equipment and new tool joint technologies. Surface torque loads are up to 100,000 ft-lbs. Tension loads when picking up from TD are also a constraint for the uppermost drill pipe.

Because of the TVD of these wells, “combined loads” (combined torque, tension and pressure when drilling and/or backreaming) are a significant design constraint.

DESIGN WORKFLOW

The drillstring design for the 10 5/8-in. hole section to TD is driven by:

1. All materials must remain within reliable elastic behavior for the expected formation temperature profile.

2. Hydraulics to achieve necessary flow rate at TD (for hole cleaning and BHA-operation reasons). The minimum annular velocity is greater than 150 ft/min and preferably greater than 200 ft/min. Surface pressures are realistically limited to under 6,700 psi (and preferably under 5,500 psi for rig reliability reasons).

3. ECDs must be acceptable for realistic variations in rheology and flow rate.

4. Tension loads must be acceptable when pulling out of hole at TD. Surface tension load should not exceed the 90% limit of premium-grade pipe. In this case, the design basis FF is up to 0.35, although most likely loads are expected to be 0.25 to 0.30.

5. Torque when rotating at TD, for FF = 0.20 – 0.25. Torque loads must be acceptable for connections, pipe body at FF = ≤ 0.25, and for peak variations at 0.3.

6. Combined loading of torque and tension must be acceptable for the 90% limit of premium-grade pipe, when drilling at TD.

7. Von Mises analysis must be acceptable at TD under full load. Design is based on temperature-corrected strengths.

8. Collapse strength must be ≥ 3,000 psi for premium-grade pipe. This allows up to 4,000 ft of pipe to be empty on top (at 11.0 ppg mud weight, with 1.25 safety factor).

9. Burst strength must be such that the pipe is able to withstand a pack-off of up to 2,500 psi when circulating at maximum flow rate (or surface pressure of 8,000 psi, whichever is greater).

DESIGN PROCESS

The design process was highly iterative. The first-pass analysis assumed standard API dimensions and weights. Hydraulics (both pump pressures and ECDs) drives the hole size and pipe size combination.

From this point, the T&D iterations commence. This resulted in a drillstring designed firstly for managing the tension and combine-load scenarios. From this point, the expected torque loads are established.

This first-pass review established surface equipment requirements and pipe requirements for a standard solution.

Based on this, a 5-in. x 5 7/8-in. x 6 5/8-in. drillstring design was selected. This combination was an effective compromise, taking into account drill pipe used in the previous hole section.

As Figures 1 and 2 show, solutions with conventional S135 drill pipe are unacceptable for tension, torque and combined torque-tension loads.

The next iterations involved making the drillstring as light as possible (via use of smaller drill pipe) for reduced loads on the top-most pipe. By reducing the loads, this also allowed “smaller” tool joints to be used (which in turn further reduces T&D).

At some point, the use of high-strength drill pipe was investigated. The immediate benefit was improved overpull and combined-load capacity on the top-most pipe. A secondary benefit was the possible use of non-standard thin-walled drill pipe (for reduced pipe weight, as well as improved hydraulics performance). Thin-walled tubes were eventually selected for both the 5-in. and 5 7/8-in. pipe. As Figures 3 and 4 show, an acceptable solution is achieved via 165 ksi material drill pipe. It is acceptable for all loading situations.

DESIGN CONSIDERATIONS

The basic design philosophy was to keep the entire drillstring as light as possible and to use higher-strength tool joints and pipe where required. Studies looked at both 150 ksi (V-150) and 165 ksi (VM-165) strength material for steel components. Also, tools joints from 120, 130, 135, 140 and 145 ksi material were evaluated. The V-150 proved adequate but provided minimal allowance for tube body wear and limited margin of safety; therefore, VM-165 is being pursued as the base case with V-150 as a back-up solution. To fulfill the lightweight drill pipe component requirements, an aluminum DP solution of 60-80 ksi aluminum alloy is being pursued as the base case option.

PIPE PERFORMANCE

The drivers for the choice of the pipe body grade are: resistance to high tension, resistance to shock, resistance to fatigue, and resistance to crack initiation and propagation. Drillstring design software calculations demonstrate that a grade with minimum yield strength of 165 ksi offers the best performance and maximum safety margin. The VM-165 grade provides optimum strength properties, with no drawbacks.

High-strength steels become usually brittle under low service temperatures, and it is very difficult to associate good performances in tension resistance and in shock resistance. Yet this is not the case for VM-165 grade drill pipe.

This steel grade, when used in drill pipe applications, associates ultra-high-strength performance – 165 ksi minimum yield strength – with high-impact toughness – Charpy V-notch energies above 44 ft-lbs at -4°C, for a 10 x 7.5 specimen. It is this performance capability that makes 165 ksi drill pipe particularly well suited for highly demanding drilling operations.

Severe drilling environments can introduce extreme mechanical loadings. Drill pipe for uERD and similar wells may see high tensile loads, fatigue, shocks and surface damage. The VM-165 grade addresses all these constraints.

High tensile loads

The VM-165 grade has a minimum yield strength of 165 ksi and a minimum ultimate tensile strength of 175 ksi. This provides excellent ability to resist to high tension loads. Typical values are collected in Table 1 and compared with those of VM-150 grade and a standard API grade.

Impact toughness measurements have been conducted as per ASTM E23. The VM-165 grade shows high impact toughness performance, even at low temperature. Table 2 shows the performances reached with VM-165 at -4°F in the longitudinal direction, for 10 x 7.5 mm specimens.

The VM-165 still exhibits a fully ductile behaviour at temperatures as low as -35°C, as shown on the transition curve (Figure 5). The ductile to brittle transition temperature is around -60°C.

High resistance to fatigue

Small-scale fatigue tests simulate the resistance of the material when loads are applied repeatedly, for example, when the pipe rotates while remaining within a dogleg. The fatigue limit of VM-165 base material was evaluated, with the use of round specimens submitted to tension/compression loads (stress ratio = -1), and a post treatment as per ASTM E739.

The number of cycles to run-out was set at 10 million. This data, compared with the fatigue limit of other drill pipe and OCTG casing grades, is compiled in Table 3. The VM-165 grade shows the highest fatigue limit.

Resistance to crack propagation

Fracture toughness and crack tip opening displacements (CTOD) have been measured on various steel grades as per ASTM E399-06. The CTOD delta value gives the maximum acceptable notch size that will not initiate a crack into the material at a given temperature. The fracture toughness value gives information on the ability of the material to absorb the energy due to a sudden shock. In both of these cases, when drilling equipment is submitted to severe loads, these values are known to noticeably decrease with steel strength.

The results collected in Figure 6 show that the VM-165 is in line with usual API grades and doesn’t demonstrate a drop of performance.

Steel chemistry

The chemistry chosen for VM-165 grade is a proprietary chemistry based on AISI 4130 material. It was developed more than 10 years ago, initially for premium casing applications. It is particularly well suited for high-strength and high-toughness performance. In particular, this grade offers:

• Very clean steel with limited amount of impurities (P, S, …).

• Optimum balance of alloying elements (C, Cr, Mo, …).

Heat treatment

The heat treatment is divided into three phases, each specifically set up to ultimately reach an optimum strength/toughness compromise. First, austenitization aims at heating the steel above AC3 point to recover a homogeneous and carbide-free austenite microstructure. Then, through the use of carefully controlled water-quenching, the material reaches a complete through-wall martensitic phase along the pipe’s length. To avoid any thermally induced cracking, a fine-tuning of the quench parameters is necessary.

Subsequently, tempering of the very hard martensite under controlled conditions of temperature and time allows the steel to reach the required strength level while maintaining a processing temperature sufficiently high to keep dislocation density to a minimum level.

Thanks to this optimized process control, the solution for ultra-high-strength /high-toughness drill pipes applications was developed, then industrialized in various combinations of outside diameter and wall thickness through the processing of several heats of material.

Tool joint performance

The drivers for the choice of the connectors are high torque capability with minimum OD and maximum ID in order to reduce weight and achieve optimal hydraulic performance.

Table 5 shows the torque performance by size of various types of connectors in addition to the requirements of the drillstring design calculations for each of the three drill pipe sizes.

The first option is standard API connector with 120 ksi yield strength. To achieve the required torque within a usable size range is not achievable.

The second connector option is a double-shoulder (DS) connection with a proprietary thread design to improve performance, and 120 ksi yield strength tool joints. The torques increase by approximately 80% on average, and acceptable sizes are reached. However, acceptable torque performance cannot be met for two of the three drill pipe sizes.

The third connector option is based on the same design as option 2, but the material yield strength of the tool joint is enhanced to reach 135 ksi minimum. This high-strength, double-shoulder (HSDS) connector meets both the torque and size requirements, for every drill pipe size. It was determined to be the most suitable connector for the project.

Drill pipe validation program

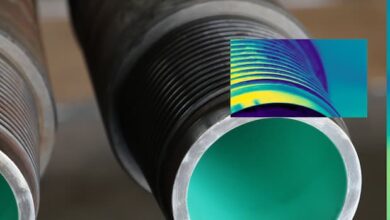

Regarding the geometry and grade requirements and choices, the chosen drill pipe assemblies for project are:

• 5 in. x 0.30 in. pipe body in VM-165 grade with 6 5/8 in. x 3 ¾ in. HSDS connector.

• 5 7/8 in. x 0.32 in. pipe body in VM-165 grade with 7 ¼ in. x 3 7/8 in. HSDS connector.

• 6 5/8 in. x 0.33 in. pipe body in VM-165 grade with 8 ½ in. x 5 ¼ in. HSDS connector.

An extensive qualification program has been set up to demonstrate product performance. It includes the production of 400 5-in., 5 7/8-in. and 6 5/8-in. drill pipe assemblies, as well as qualification tests to be performed during Q4 2008 and Q1 2009.

The qualification tests are summarized in Table 6. The first section deals with small-scale laboratory tests on the pipe body, which confirm that the VM-165 grade is reached on the specific pipe sizes. The second section deals with laboratory tests performed on full-scale drill pipe assemblies. The tests are chosen to be representative of real use conditions. The results confirm that the drill pipe assemblies meet all the field expectations.

In particular:

• Tension and torque tests evaluate the performance of the weld when the drill pipe assembly is submitted to various combinations of loads.

• Fatigue and fatigue with slip marks tests evaluate the fatigue performance of the drill pipe assemblies, with and without surface damages.

• Shear, BOP and Iron Roughneck tests evaluate the suitability of the rig equipment, and their ability to deal with the specific products: shear rams will be tested to shear the pipe body; the Iron Roughneck will be tested through several hundreds of high makeup and breakout torques.

The last section deals with field tests. Pipes will be run in real drilling operations to confirm field use capability and field performance. Inspection procedures will be closely monitored.

KNOCK-ON EFFECTS

Logically, when new technology is developed in one area, it should be expected that there is likely to be knock-on effects in other areas. In this regard, the advancements of drill pipe technology are no different. On the positive and most importantly, it stretches the technical limit beyond what is currently thought possible. Technically speaking, if the VM165 is properly deployed, it will allow access to previously unobtainable hydrocarbon reserves. On the downside, a leap forward with one technology requires the advancement of others.

The development of high-strength, thinned-wall pipe has necessitated the requirement to alter fundamental rig design. To allow for safer and more efficient running of drill pipe, more rig floor space and pipe barn area was added. Over 20,000 ft of drill pipe can stand back in the derrick, and another 20,000 in full stands can been picked up or laid down in the pipe barn.

To allow for nearly 80 ft of drill pipe stretch when tripped off bottom, over 20 ft was added to the height of the standard derrick. This will allow for picking up and working pipe and casing of bottom. The BOP systems had to be enhanced in order to increase their ability to shear drill pipe of up to 180 ksi yield and to shear thick-walled pipe ADP nearly 0.625-in. thick. Slips had to be tested to confirm their ability to grip but not crush or damage thin-walled pipe. Slips had to be tested to confirm their ability to grip and hold high-strength tools joints (130-150 ksi) while making and breaking.

In many cases, the development of the 165 ksi pipe means dramatically new equipment or significant modifications to handle higher loads more safely. Several changes were in pipe-handling equipment:

• Top drive system capable of 150,000 ft-lbs and 120 rpm.

• Iron Roughneck capable of 150,000-200,000 ft-lbs makeup and breakout.

• Bucking machine capable of makeup and breakout of up to 150,000-200,000 ft-lbs.

To a similar extent, changes in equipment run in the drillstring along with the drill pipe like cross-over subs, mechanical friction reduction devises, safety valves, pipe in subs, kelly valves heavy weight, drill collars and BHA accessories all had to be modified. Repair, maintenance and inspection are also undergoing more scrutiny and will likely be changed.

CONCLUSIONS

Modeling strongly suggests that the uERD project is technically feasible but requires the development of the next generation in drill pipe technology.

In every well design case, the VM165 triple taper design – 6 5/8-in. x 5 7/8-in. x 5-in. – with the high-strength tool joints satisfies the torque, tensile and hydraulic performance requirements with sufficient safety margins. The 135k tool joints along with broadening connection performance makeup envelope will definitely add value.

This means that having a connection with a wider make and break window will reduce fatigue of tool joints and surface running equipment. The leap from 150 to 165 ksi is monumental in improving the ability to reach extended targets, but, in actuality, with respect to chemistry and connection design, these are simply enhancements to existing technology.

To date, five sizes of VM-165 have been successfully manufactured, and lab tests have been conducted. All small-scale test results either meet or exceed a strenuous purchase specification. The knock-on effects have been significant but not insurmountable, and, once combined with the 165, will allow drilling to push well beyond the current drilling envelope. This project is evidence that even with a tight time line – it started just two years before projected spud – collaboration works. Final proof will be in the execution.