Kuwait Oil study targets main causes of hand injuries

By Garry Gopaul and Ahmad Al-Shatti, Kuwait Oil Company

Controlling hand injuries is a significant challenge for the drilling industry, clearly illustrated by IADC statistics, and not too surprising given the intensive interface involving use of hand and power tools. Among Kuwait Oil Company (KOC) drilling operations, hand injuries are also observed to be the most common LTI for drilling contractors. The operator undertook a study, covering local and international drilling contractors and service companies, to identify the main factors contributing to this result.

The first objective was to analyze observations, interviews and a review of past LTIs in order to identify the main causes that contribute to hand injuries in the categories of people, process and plant. The second goal was to develop recommendations to reduce hand injuries in a sustainable manner.

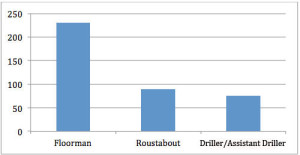

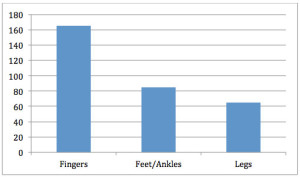

Figure 1 shows the most frequent LTIs by body part, according to IADC statistics from 2012. Approximately 40% of injuries were related to hand and fingers, significantly more than any other body part. Figure 2 shows that, as in previous years, the floorman position suffered the most LTIs.

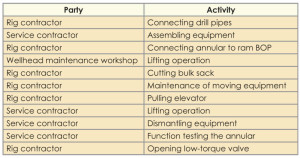

During the KOC study period from 2009 to 2013, there were 11 hand injuries classified as LTIs within KOC D&T operations, summarized in Table 1.

To identify potential causes for hand injuries, the following data-gathering activities were conducted at rig sites:

• Various jobs on the rig floor were observed for the nature of interaction between worker hands and equipment;

• Job safety analyses for these jobs were reviewed to compare documented and actual controls being implemented;

• Training records of floormen were reviewed; and

• Interviews were conducted with floormen and toolpushers regarding contributing causes of hand injuries, based on their working experience.

The site visits covered 11 rigs from two local and three international rig contractors and included two international service companies.

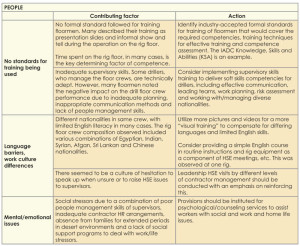

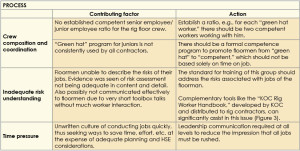

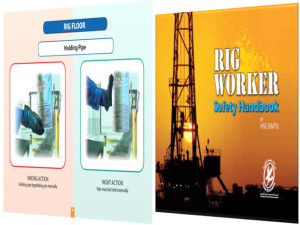

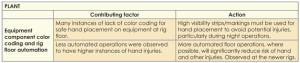

Tables 2 to 4 detail contributing factors from the observations and interviews, separated into the categories of people, process and plant. Potential actions to address those factors are also listed.

Analysis of previous incidents

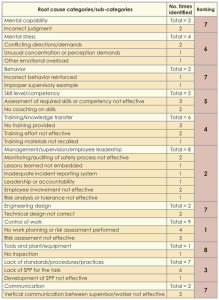

Incident investigation reports for LTIs associated with hand injuries during 2009-13 were reviewed to identify root causes as shown in Table 5. This revealed that root causes associated with control of work and leadership contributed to 50% of incidents.

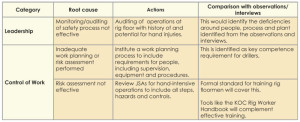

For the two main root causes, corrective actions are listed in Table 6. This enabled a comparison with the information obtained from the observations and interviews to be made.

Conclusion

This study focused on identifying contributing causes to hand injuries in drilling operations, based on practical and proactive insights obtained from observations and interviews on the rig floor and by examining the root causes associated with previous LTIs.

The former revealed key contributing factors to be:

• Inadequate training standards

• Language barriers and work culture differences

• Crew composition and coordination

• Inadequate risk understanding

• Perception of time pressures

• Mental/emotional issues

While automated operations will reduce the number of hand injuries, this was not identified as a significant factor.

The incident investigation reports revealed deficiencies around:

• Control of work. Inadequate work planning to assess adequacy of people, equipment and procedures, assessing risk and communication, monitoring of ongoing work, auditing of work to identify deficiencies and recognizing potential for injury and stopping work.

• Leadership. Inadequate auditing by varying levels of leadership, focused on jobs with high potential for hand LTIs would reveal many, if not all, of the above factors.

If effectively implemented, the recommendations will not only improve hand injuries but also aid in reducing other types of injuries and improve operational efficiency.