Maersk Oil to use Alcoa Aluminum Drill Pipe for well maintenance, abandonment

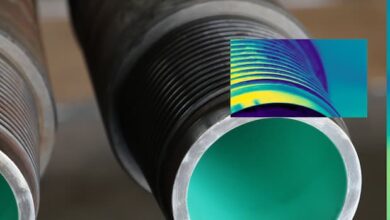

Maersk Oil will use 10,000 ft of 5-in. Alcoa Aluminum Drill Pipe (AADP) in maintenance and abandonment operations, Alcoa Oil & Gas announced yesterday at the 2014 IADC/SPE Drilling Conference in Fort Worth, Texas. The AADP, which will be supplied through AMRTUR Corp, will be fitted with modified API FH connections and include an NOV TK-34 AL coating for corrosion resistance.

Alcoa’s drill pipe design and aluminum construction make it 40% lighter than steel pipe, reducing frictional drag and enabling operators to drill further horizontally. Anti-corrosive properties also can mean greater durability and operating life, according to the company. In addition, a proprietary thermal connection technology allows steel tool joints to be attached to the aluminum pipe body, making them compatible with conventional oil and gas rigging practices.

“World-class companies such as Maersk Oil are seeing the benefits of Alcoa’s aluminum drill pipe given its lighter weight, higher strength and durability,” said Tim Marvel, Managing Director for Alcoa Oil and Gas. “These characteristics help reduce overall operational costs and enable operators to drill about 20% further than with traditional steel pipes.”

AADP had previously been deployed in complex, extended-reach wells. In 2012, Brunei Shell Petroleum deployed 1,800 meters (5,905 ft) of aluminum drill pipe offshore Brunei. Since then, Alcoa has provided an additional 20,000 ft of its pipe for operators in the Eastern Hemisphere.