MPD system facilitates top-hole drilling offshore Brazil

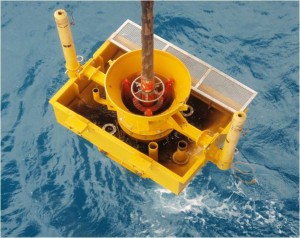

AGR has completed its first Brazilian operation using the EC-Drill system, a managed pressure drilling (MPD) technology based on the RMR system and modified for Petrobras’ jackup operations. The technology application on two Brazilian wells in the Rio Grande do Norte region was the first time that AGR has provided dual gradient drilling (DGD) services to Petrobras.

EC-Drill allows operators to actively adjust the drilling fluid level in the conductor, allowing accurate manipulation of bottomhole pressure for more effective drilling.

For Petrobras, the system significantly improved drilling of the top-hole sections on the two wells. All mud and cuttings were returned to the rig without discharge to the sea, minimizing the environmental footprint, and bottomhole pressure was manipulated to compensate for ECD. The amount of drilling fluid lost to the formation was also minimized while running and cementing the surface casing.

Petrobras contract manager José Fernandes said, “The AGR system effectively helped in controlling the pressure inside the well, reflecting positively on combating the fluid losses and reducing operational costs.”

Terry Scanlon, senior vice president AGR Americas, said, “We are pleased to report that Petrobras is now experiencing the enhanced drilling results that we committed to deliver with our environmental and DGD capabilities. Petrobras has been an excellent partner in this program, and we are continuing with them to fine-tune system capabilities for further wells offshore Brazil in the near future.”

The Rio Grande do Norte wells were the first two projects following a series of two-year services contracts signed between AGR and Petrobras in 2010.