New BOP design eliminates need for elastomeric seals

By Katie Mazerov, contributing editor

Enovate Systems, an Aberdeen-based provider of well control technology, has developed a product that replaces the BOP riser package design with a system that combines gate valves and a new shear system. The En-Tegrity Shear Seal Valve provides complete metal-to-metal environmental sealing, eliminating the need for elastomeric seals and improved cutting capacity over current BOP designs, company spokesman Tony Kitchener said.

“Today, well control in drilling and production operations is currently achieved with either conventional BOP technology or gate valves, both of which have limitations, such as reduced cutting capability and pressure limitations,” Mr Kitchener said. “Conventional systems also have limited life in high-pressure, high-temperature and extreme environments due to limits of elastomeric sealing elements. We believe we have a solution that delivers improved cutting and sealing capacity and eliminates problems that typically occur with conventional shear systems,” he continued. “For example, with conventional BOP systems, internal pressure resists closure. This design provides increased cutting capability and allows wellbore pressure to facilitate closure.”

A 7 3/8-in. version of the En-Tegrity system is scheduled to be deployed for a major operator on Australia’s North West Shelf, with delivery of the first unit planned for May 2013 and an additional 10 to 14 units delivered later in the year. A 13 5/8-in. model has undergone extensive testing, and the company hopes to introduce the first unit in early 2014. Two major operators have expressed interest in that version.

In addition to the two sizes currently in development, Enovate is seeking joint industry project partners to assist with funding of a design of an 18 ¾-in. model for running various sizes of tubulars and casing. Development of that version will take two to three years, Mr Kitchener said.

Two-stage piston operation

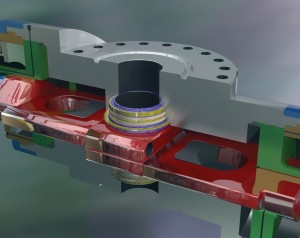

“The En-Tegrity system takes us away from the ram-type valves in conventional BOPs by utilizing gate valves that provide superior sealing capability in combination with a very effective shearing device that delivers much greater force,” Mr Kitchener said. The design features a two-stage piston operation, with the first piston generating the cutting force and the second moving the gate valves into the closed position from opposing sides. The testing, primarily with the 7 3/8-in. size, has been validated by several major operators. “We can generate 1 million lbs of force with this size,” he continued.

Each valve has two independent barrier elements that provide metal-to-metal seals throughout the operation, Mr Kitchener explained. “The process is very simple, using conventional gate valves in a new way as the gate valves provide a bi-directional sealing capability that protects the critical sealing areas during the close/shearing operations,” he said.

The metal-to-metal sealing also provides an extended temperature envelope, improved chemical compatibility and a more rugged sealing environment that is resistant to erosion, all of which results in reduced maintenance. The En-Tegrity system enhances safety by separating the shearing and sealing functions, ensuring that the sealing area of the gates is unaffected by any metallic fragments.

While the system is particularly suited to subsea applications, it can be applied for platform-based operations and land wells. “There are no depth restrictions,” Mr Kitchener said. The company is also looking at ways of integrating components of the En-Tegrity system into existing BOP designs.