Reliability-centered maintenance program reduces downtime, results in 63% ROI

By Joanne Liou, editorial coordinator

Although a combination of people, processes and assets has driven significant strides in safety in the industry, efforts to improve equipment reliability lags behind. “We need to take the same journey around reliability – make that same step-change we made to safety around reliability,” Dirk Kolnsberg, director- enterprise asset management project, Ensco, said at the IADC International Deepwater Drilling Conference and Exhibition in Rio de Janeiro on 18 April. Ensco’s reliability-centered maintenance (RCM) program has resulted in a 63% return on investment (ROI) since 2010, according to Mr Kolnsberg.

RCM is a process used to manage assets to operate consistently and prevent them from failing. “Failures affect many parts of a business,” Mr Kolnsberg said. “From a safety (point of view), if you have a failure, you have to send somebody out there for repair … putting themselves essentially in harm’s way.” RCM has been used in other industries, including commercial aviation, the military and nuclear energy, and it is developed with consideration to the complexity and inter-dependency of equipment and systems, according to Mr Kolnsberg.

RCM assessment process asks seven key questions:

- What do we want the system to do?

- How can it break? (Functional failure)

- Why did it break? (Failure mode)

- What happens when it breaks? (Failure effect)

- Why do we care? (Failure consequence)

- How can we stop it from breaking? (Maintenance strategy)

- What if we cannot stop it from breaking?

In August 2010, Ensco implemented its RCM program, bringing together personnel from toolpushers and drillers to maintenance technicians and engineers, from OEM personnel to reliability consultants. The group focused on the top pieces of equipment in the pipe-handling system known to cause downtime, such as bridge racker, racking guide arm and horizontal to vertical machine.

“We developed action items – 72 total – things we needed to do, things we needed to change, whether it was maintenance routines, spare parts, redesign, talking to the vendor. These were action items we undertook,” Mr Kolnsberg explained. Ensco ended up revising eight maintenance routines and developing 15 new ones. “More maintenance isn’t necessarily the best thing, but what we try to do is look at how it can fail and identify it early to make sure we have a routine that will address it,” he added.

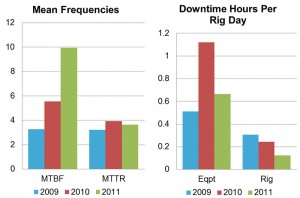

Improvements in equipment availability and reduction of critical path downtime have been realized. “We almost doubled the mean time between failure (from 2009 to 2010), which means we don’t have as much critical path downtime,” he said. The downtime hours per rig per day also reflect improvement to less than one-fifth of an hour in 2011.

Conservatively evaluating the revenue linked to RCM efforts – US$995,400 – against the cost of implementing the program – $610,000 – produces an ROI of 63%, Mr Kolnsberg explained. By developing a culture of reliability alongside a culture of safety, RCM has the potential to improve equipment reliability to boost revenue, support more efficient and safer maintenance practices, and optimize inventory.

So proud of you brother.