Ronald Sweatman, RS Consulting: ‘Well Cementing Operations’ to fill knowledge gap for engineers, rig crews

By Alex Endress, Editorial Coordinator

Ronald Sweatman’s interest in oil and gas began when he was only 6-years-old, as his father – an oilfield general superintendent – brought him on trips to drilling rigs around south Louisiana. Mr Sweatman’s curiosity developed into an appreciation for cementing operations as he grew older. “Quite a few of the visits that my dad took me on – they were doing something special like a cement job, and that was the start of the interest,” he recalled.

Years later, while studying chemistry at Louisiana State University (LSU) in the 1960s, Mr Sweatman took the chance to work as a roustabout on land and marine wells and production facilities in Louisiana in between semesters. He left the school just before graduating, however, for a job at an oilwell cement manufacturing plant near Slidell, La. Here, Mr Sweatman was able to hone his chemistry skills in a cement laboratory before heeding his father’s advice: “My father said, ‘Maybe it’s time for you to go out into the field.’ ”

In 1974, Mr Sweatman joined BJ Services Co, then part of Hughes Tool Co, as a District Engineer for the Gulf of Mexico and Gulf Coast region. While with the company, he resumed his education through the company’s self-titled BJ Hughes’ School of Engineering. Due to credits earned during his time at LSU, he was able to complete his certified engineer diploma in just one year. “They trained me in cementing, fracturing and acidizing, and the different types of pumping services that you do on a rig,” he said.

Mr Sweatman ended up staying with BJ Services for 17 years before leaving in 1990 to manage offshore hydraulic fracturing and cementing operations in the North Sea and Europe for a start-up company, Western Co. By 1995, he had joined Halliburton as a Cementing Technical Analyst for the Gulf of Mexico and Gulf Coast. He was eventually promoted to the role of Chief Technical Professional, assisting in the development of major commercial projects. This role allowed him to diversify his areas of expertise, including reservoir management, lost circulation control and enhanced oil recovery.

In January 2015, Mr Sweatman launched his own Houston-based consulting company. RS Consulting specializes in reservoir development challenges in E&P projects, enhanced oil recovery, gas storage and geothermal energy.

Over the course of his 40-plus year career, Mr Sweatman said, he’s most proud of the contributions he’s made to the drilling industry’s safety gains.

His experiences making rig visits with his father, when he witnessed injuries caused by equipment malfunctions, stuck with him and inspired him to make rigs safer. “Those events made me want to look for ways to improve things that would not cause those problems,” he said.

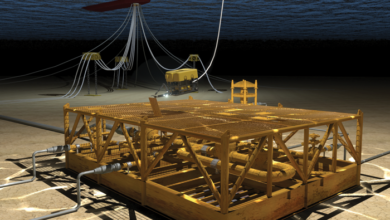

For a decade, he pursued this goal by serving as chairman of the API Zone Isolation Task Group from 2000 to 2010. During this time, he helped to work on RP 65, Parts 1 and 2, which refined best practices for cementing. “The guidelines we released help crews prevent shallow-water flow in deepwater,” he said. “They also help crews prevent flows of oil and gas that could not only cause the cement operation to fail but have worse consequences for the equipment and the people, such as a blowout.”

Further safety gains are now being made in the industry through better downhole sensors that enable real-time monitoring of cementing operations. Such technologies help rig crews to “observe abnormal flows that might create a problem and fix them, instead of waiting until things get bad.”

Mr Sweatman has authored more than 100 technical publications and invented 44 patented technologies in the areas of well cementing, well integrity, reservoir flow monitoring/control, hydraulic fracturing, drilling fluids, wellbore strengthening and geothermal energy.

His newest book, being launched in May, is called “Well Cementing Operations”. The book was guided and peer-reviewed by the IADC Technical Publications Committee over the course of nearly a decade. The committee periodically recruits drilling professionals to write books on their respective field of expertise.

Mr Sweatman’s book will fill what he refers to as a “gap in knowledge” for well cementing operations and best practices. The most recent peer-reviewed book on the topic was published in 1989 and was meant only for engineers.

Mr Sweatman’s book, on the other hand, was written with the goal of educating readers with a wide range of technical understanding – both engineers and rig personnel, such as drillers, toolpushers, roughnecks or roustabouts.

“We hope to have a wide readership,” he said. “Through this book, I would like to promote a better industrywide understanding and acceptance of cementing best practices to newcomers and experts alike.”

Click here to watch a video interview with Ronald Sweatman.

Click here to order Ronald Sweatman’s book.