Statoil looks to permanent reservoir monitoring tools to increase oil recovery

Statoil and partners have determined that using permanent reservoir monitoring (PRM) seismic tools will result in 30 million extra barrels of oil from Snorre and Grane, two oil fields with large remaining reserves. With current oil prices, Statoil estimates that it could recover additional oil at a value of NOK 19 billion on these two fields.

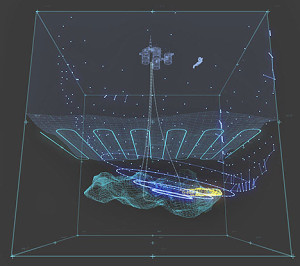

Approximately 700 km of seismic cables will be placed in trenches on the seabed of the Snorre and Grane fields. The area combined totals approximately 240 sq km (190 on Snorre and 50 on Grane). Installation work will begin in 2013 at Snorre and in 2014 at Grane.

“Better seismic data is essential to the company’s strategy for increased oil production. This is a very important project for Statoil,” Øystein Michelsen, executive vice president for development and production on the Norwegian shelf, said. “This technology is an important contribution to reaching our ambition of increasing the recovery rate for oil to 60% from our fields on the Norwegian shelf.”

The conventional gathering of seismic data involves towing streamers after a ship, which transmits a sound signal. PRM technology involves embedding the streamers into the seabed on a permanent basis. When Statoil wants to collect seismic data, a ship with a signal source will cross the field. The cables on the seabed will register the signals and transmit them to the platform and onshore for interpretation.

“This will give us a picture of the changes in the reservoir over time, which is important in order to position the wells more correctly so as to recover as much as possible from the field. We have long experience in monitoring the oil and gas reservoirs, but this is the first time Statoil applies a permanent system,” Bjørn Kåre Viken, acting head of Technology Excellence in Statoil, said.