Successful dual-gradient system follows nature’s pressure profiles

By Katie Mazerov, contributing editor

A dilution-based dual-gradient system has been shown to deliver significant cost reductions and enhanced well control in deepwater wells. “This is an alternative way of creating a dual-gradient profile in the wellbore, not by means of pumping heavy mud from the seafloor up to the surface but by diluting the riser and creating a different pressure profile at the seabed,” said Luc de Boer, president of Dual Gradient Systems, which collaborated with Transocean in the development of the system. Mr de Boer discussed the testing process in a presentation at the IADC Dual Gradient Drilling Seminar on 19 March in Milan, Italy.

The premise of Transocean’s continuous annular pressure management (CAPM) system is based on using two stable mud densities in the wellbore, a specially designed centrifuge and a rotating control device (RCD) near the top of the riser below the slip joint rated to 1,500 psi.

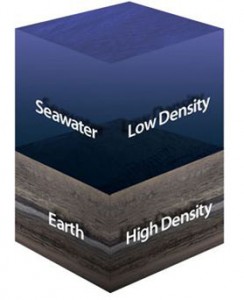

The $5 million research and development project was conducted over a five-year period. The system is designed to follow the earth’s profiles – the ocean being low pressure and the earth being high pressure – rather than fight them, Mr de Boer noted.

“Initially, the system was designed conventionally, where heavy mud was pumped down the drill string through the bit and up the annulus,” he explained. When Transocean joined the project, the company suggested the use of an RCD to pump the mud. “At the bottom of the riser, the same mud without barite is injected into the return mud stream, creating a lower-density mud in the riser,” he said. An RCD at the top of the riser holds back pressure and directs flow to a choke manifold. Flow meters accurately track barrels in and out of the well. “The control device is at the surface, which also services as a very good safety feature,” he added.

Continuous separation

Testing began in 2002 with the concept to separate the oil-based mud into a high-density mud and a nearly un-weighted mud on a continuous basis. A second phase was launched in 2004 testing an oil-based mud and a water-based mud. In a third test in 2006, a special centrifuge unit with better capacity than a single centrifuge unit was deployed. The final test in 2007 achieved the desired separation process with a specially designed centrifuge that increased the flow from the normal pump rate of 50 gal/min to 600 gal/min, Mr de Boer explained.

In a comparative test in a deepwater Gulf of Mexico well, the conventional single-gradient well design included nine casing and liner seats to total depth (TD). The dilution-based, dual-gradient well design had six casing and liner seats, with a high-density mud weight of 12.8 lb/gal to 16.3 lb/gal, a riser mud weight of 9.9 lb/gal to 11.3 lb/gal and a dilution ratio of 2.4 to 3.1. “The reduction in casing strings, at $10 million per string, is significant,” Mr de Boer pointed out.

A third scenario featured a dual-gradient drilling (DGD) design with dilution below the mud line. The system resulted in four casing and liner seats, with a high-density mud weight of 17.3 lb/gal, riser mud weight of 10.9 lb/gal and a dilution ratio of 2.9. “We call this the prize,” Mr de Boer said. “This design takes more work to get the dilution below the seabed, but it gives us extended reach.” The dilution-below-mudline system also can be used for low-cost open-hole sidetracks and for low-cost exploration drilling.

With the DGD dilution system, all equipment is on the surface and can be repaired with little downtime; the CAPM riser system and flow controls enhance well control. The system also can be switched from dual-gradient to single gradient in an hour if necessary, Mr de Boer said.