News Cuttings

RAPID-S53 JIP launches new phase with reduced fees

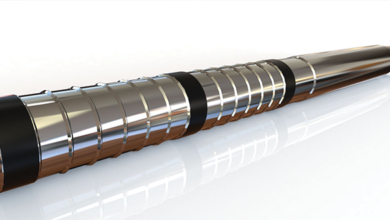

RAPID-S53, a joint industry project (JIP) between IADC and the International Association of Oil and Gas Producers to improve BOP reliability, has launched its latest phase featuring reduced fees for participating companies.

The JIP, which originated from a data-gathering effort by seven offshore contractors in 2015, has been restructured to continue on an ongoing basis, with fees adjusted annually.

For 2018, fees for operator participants are $35,000. For drilling contractors, fees for companies with subsea BOPs are $20,000, and fees for surface-only BOP companies are $15,000. Fees for onshore contractors are $10,000, and equipment manufacturers will pay $15,000. Those figures are significantly less than what most participants paid for Phase II of the JIP.

It is anticipated that most of the 30 companies that participated in Phase II will continue their involvement with the JIP. Further, one new offshore contractor recently joined the effort – Odebrecht Oil & Gas of Brazil.

The JIP has been sharing selected learnings from the data with industry groups, including the API Standard 53 Subcommittee.

At the recent API Winter Standardization conference, JIP members provided information learned regarding regulators, shuttle valves and SPM valves. A data quality workshop for all RAPID-S53 participants was also recently hosted by Pacific Drilling, with more than 50 people in attendance.

The JIP worked with both the US Bureau of Safety and Environmental Enforcement and the Bureau of Transportation Statistics (BTS) to produce their 2016 report on equipment failure reporting, required under the Well Control Rule. The JIP is currently working with BTS on the 2017 report.

RAPID-S53 stands for Reliability and Performance Information Database, designed to collect data on BOP performance as specified in API Standard 53.

Click here to learn more about RAPID-S53.

IADC Accreditation department Passes ISO 9001 recertification Audit

IADC’s Accreditation Department (ACD) has passed the ISO 9001:2015 recertification audit with zero findings and a commendation for improvement since the previous audit. ISO 9001:2015 sets out the criteria for a quality management system. It is based on a number of quality management principles, including a strong customer focus, the motivation of top management, the process approach and continual improvement.

“It is important that IADC’s accreditation division, as an accrediting body that holds training providers to course and quality standards, holds itself accountable for the quality of the services delivered to the industry,” said Brooke Polk, IADC Director – Program Development & Technology. “Obtaining the ISO recertification ties directly to ACD’s core mission of commitment to providing customer satisfaction with the highest quality products and services.”

IADC introduces new cybersecurity guidelines

The IADC Cybersecurity Subcom-mittee, which operates under the IADC Advanced Rig Technology Committee, has developed the new “IADC Guidelines for Baseline Cybersecurity for Drilling Assets.” Dr Siv Hilde Houmb, Chief Technology Officer for Secure-NOK, leads the subcommittee.

The guidelines provide baseline guidance on cybersecurity for oil and gas drilling assets and draw from the NIST Cybersecurity Framework and international standards. They can be used as a starting point for developing more robust cybersecurity protection. “The guidelines represent best practice for cybersecurity for drilling assets and were developed collaboratively by drilling contractors, operators, vendors and cybersecurity experts,” Dr Houmb said.

Click here to access the new guidelines.

IADC ULL student chapter members tour M-I Swaco