GOM, Norway case studies show how dual-physics imaging enhances geological characterization in real time

Technology delivers high-definition resistivity, acoustic images while drilling in oil-based mud, enabling more informed decision making

By Vera Krissetiawati Wibowo and Chandramani Shrivastava, Schlumberger

Borehole imaging has many applications for drilling geomechanics, reservoir characterization and production optimization. With the advances in logging-while-drilling (LWD) technologies, applications of image logs have widened to support real-time operations and decisions.

However, non-conductive mud poses a barrier for resistivity-based high-definition imaging, which limits the application during drilling with oil-based mud (OBM) or synthetic-based mud. Experience over years has suggested that geological features respond better to resistivity-based imaging than any other method.

Operators drilling in OBM face challenges determining depositional facies in reservoir evaluation workflows. Wireline images have served as a conventional solution for such applications because of the high-quality data made available, but this conveyance is not always possible due to economical and operational challenges. Because wireline logging is conducted after drilling is completed, operators have already missed opportunities to acquire images for many real-time drilling-related decisions.

Moreover, in extended horizontal, long-reach wells, running borehole images in wireline conveyance poses much higher challenges and risks than operators are normally willing to take. Real-time data transmission capability of while-drilling images adds a new dimension. More and more, geosteering operations need high-resolution images on the drilling bottomhole assembly (BHA) to navigate through complex geology and maintain a high net-to-gross for the well being drilled.

In LWD, the ability to acquire high-resolution borehole images in OBMs has been a challenge for many years. Since their development in the 1990s, a variety of LWD measurements have been made with azimuthal capabilities. In OBM, this includes density, photo electric factor (PEF), natural gamma ray and ultrasonic measurements. However, because most of these measurements have inherent low resolution, the images are not sufficient for geological characterization or many real-time applications. These low-quality images, such as density and PEF images, use chemical sources and do not provide the level of detail that operators require to make informed drilling decisions.

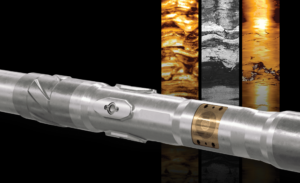

Operators demand solutions to help overcome the barrier of obtaining photo-realistic borehole images in nonconductive mud while drilling and to enable efficient decisions that increase the success of wells. The TerraSphere high-definition dual-imaging-while-drilling service from Schlumberger delivers real-time high-resolution resistivity and acoustic images while drilling in OBM environments.

Singular image acquisition for subtle features at high resolution could miss many important subsurface events, thereby constraining the optimal characterization of subsurface and downhole conditions. To properly understand, characterize and demystify the subsurface, the industry’s first multi-measurement imager was developed with high-resolution capabilities in OBM with ultrasonic and electromagnetic (EM) measurements physics.

Industry-first technology advances for borehole image acquisition in OBM were made possible with deployment of multi-sensor, multi-physics technologies of EMs and ultrasonic on one small sub. Four operational frequencies of EM measurements are used for resistivity imaging to cover different resistivity ranges in the subsurface, while ultrasonic images are made at two frequencies to account for variation in mud density and borehole wall rugosity during drilling. This enables feature identification of subtle variation in texture, structure, sedimentation and diagenesis style.

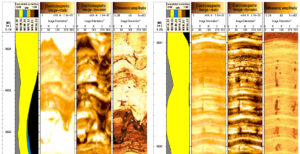

The resistivity images, which come from EM measurements, are rich on bedding features, textural details, sedimentary structures and tectonic events, while the ultrasonic images are more sensitive toward drilling-related features, such as borehole breakout, induced fractures, borehole rugosity and ledges, in addition to natural fractures. The real-time capability enables operators to optimize the drilling parameter provided through detailed borehole shape and stability analysis.

Both resistivity and ultrasonic images provide valuable information related to subsurface complexity, and real-time capabilities enable more informed and efficient decisions while drilling, resulting in immediate geosteering and drilling optimization.

The availability of this novel high-definition dual-physics imaging in OBMs enables full combination of sourceless BHA and acquisition of advanced formation evaluation while drilling or geosteering. High-definition dual-physics images allow near-wellbore geological interpretations never achieved before while drilling. This radioactive-free BHA enables operators to continue their development projects despite stricter government regulations to mitigate environmental risks while maintaining their leadership in environmental stewardship.

Technology

Operators recognized the need for a high-definition LWD imager that could provide both micro-resistivity and ultrasonic images to characterize the subsurface in detail with complementary information. Ultrasonic imaging while drilling was a challenge, especially for designing transducers capable of working in a wide range of mud weights. However, the biggest technology barrier was to overcome the OBM for resistivity imaging.

The high impedance from the mud-layer in the gap between the sensor and the formation was overcome with higher operating frequencies that improve the capacitive coupling through the mud to mitigate the effect of insulating mud.

Both acoustics and resistivity imaging sensors are positioned within a single compact 15-ft drill collar. High-resolution EM pulses are sent through the mud from the sensor to the formation at a wide range of frequencies that produce best-quality resistivity images across the broad range of resistivities encountered in subsurface geological environments. An innovative methodology for data compression was deployed for high-quality real-time data.

The acoustic subsystem emits short ultrasonic pulses and detects the resulting echoes from the borehole wall, providing robust measurements in a wide range of environments, including heavy mud-weight drilling fluids with high attenuation. Frequent sensor sampling and focusing deliver high-resolution images. The four sensors are positioned 90 degrees apart around the collar, orthogonal to each other.

In addition to the dual-physics images, hole shape information is also transmitted from the ultrasonic calipers.

To provide real-time data for both high-definition ultrasonic and resistivity images in mud pulse telemetry transmission, extensive automated processing is required downhole. For the resistivity, the four frequencies are combined into an apparent resistivity image that is transmitted in real time using mud-pulse telemetry.

Compression of ultrasonic images is a challenge because of factors such as standoff effects. Formation features tend to be very fine scale with low contrast in acoustic impedance, and artifacts such as bit scratch marks are common. Ultrasonic amplitude images can be transmitted in real-time through mud-pulse telemetry.

Both image physics collocated in one tool provide a complete solution for detailed geological and borehole understanding in OBM environments while drilling. The images are complementary. The resistivity images acquire details of subsurface geological variations, while the ultrasonic images are more sensitive to drilling effects, stress-related features and borehole conditions.

Real-time full-borehole coverage for unambiguous interpretation helps reduce rig time and costs. In addition to enhancing geosteering in complex environments, the determination of production potential and reserves estimates is accelerated; and subsequent operations, such as wireline runs, are optimized.

The high-resolution EM pulses of the high-definition dual-imaging-while-drilling service enable a wide range of firing frequencies. The service produces the desired high-quality resistivity images across the broad range of resistivities encountered in subsurface geological environments, including clastics, carbonates, shales and evaporites. Operators in the Gulf of Mexico and in Norway have used the service to optimize operations.

Gulf of Mexico

An operator in the Gulf of Mexico drilling in deepwater Miocene reservoirs sought a while-drilling method to acquire high-borehole images without compromising image quality. Steep dips close to salt domes and the presence of potential fluid conduits from faults or fractures created a challenge. Borehole degradation posed risks for open-hole wireline logging.

Using the high-definition dual-imaging-while-drilling service, the operator acquired images with a significantly higher resolution in the OBM environment compared with images provided by previous-generation LWD imagers. This resolution enabled recognition of thin laminated beds, bedding deformation, facies variations and onset of drilling-induced features.

Another operator in the Gulf of Mexico needed to quickly perform a formation evaluation, identify the oil/water contact (OWC) and optimize the completion interval while drilling development wells in an OBM environment. Previous drilling of development wells showed that borehole instability limited the time window to keep the hole open in a thinly laminated reservoir with low resistivity contrast. Conventional triple-log combo logs did not provide sufficiently accurate evaluation of hydrocarbons in place and potential free fluid.

The operator used a combination of the high-definition dual-imaging-while-drilling service and a multifunction logging-while-drilling service for a comprehensive logging suite in a deviated well to be drilled with OBM. This would enable real-time transmission of LWD triple-combo logs, spectroscopy, sigma and resistivity images to identify reservoir sand intervals to make informed drilling decisions.

An efficient interpretation on the recorded-mode images offered full evaluation of the reservoir structure, texture, fluid in place and OWC for the completion design. The system provided geological interpretation and petrophysical evaluation of the lithofacies, which provided understanding of the reservoir architecture and its potential producibility.

High-definition ultrasonic and resistivity recorded-mode image data helped define the geological structure, sand lamination and sand texture. Real-time logs confirmed the conventional hydrocarbon sands interval. The EM sensors of the high-definition dual-imaging-while-drilling service confirmed the OWC in the low-contrast laminated sand. Water saturation was used as the primary fluid volume estimation. Measurements from the multifunction LWD service enabled the analysis of movable fluid in the formation in the drilling pass.

The recorded-mode LWD logs were quickly interpreted and tailored to highlight completion intervals. The solution ended up providing efficient optimization of the completion interval.

Norway

In Norway, government guidelines require operators to mitigate risks, decrease operational footprint and reduce critical activities such as the use of radioactive sources for logging operations, especially in sensitive areas.

Using the high-definition dual-imaging-while-drilling service run with reservoir mapping and advanced formation evaluation-while-drilling services, an operator in the Norwegian Sea ran the first global geosteering operation using comprehensive real-time data governed by a chemical-sourceless BHA in OBM. The combination facilitated optimal well placement with higher net-to-gross ratio in a challenging geological environment and enabled the well to produce above predicted rates.

Another operator offshore Norway planned to drill a horizontal well in the upper part of a sand body injected with shales in the Balder Field. Combined with uncertainty in the sand properties and distribution within these zones, the shale stability presented a challenge that required high-resolution borehole imaging to delineate. The use of OBM in the well prompted the operator to select the high-definition dual-imaging-while-drilling service for the use of EM and ultrasonic imaging technology. The service enabled high-definition visualization of complex Balder injectites. The service delineated thin and non-constructed sands injected perpendicular and parallel to shale bedding. This removed ambiguity on conventional log responses and validated questionable reservoir zones for inclusion in completions. The ultrasonic images captured weak-plane failure in the shales down to the scale of millimeters.

Operators demand solutions to help overcome the barrier of obtaining photo-realistic borehole images in nonconductive mud while drilling and to enable efficient decisions that increase the success of wells.

A third operator in Norway required high-definition images while drilling a sidetrack offshore. The operator expected the well to run through a complex clastic shallow marine and fluvial sequence. Delineation of the expected thin and variable interbeds of sandstones, claystones and coals in the OBM created challenges with conventional LWD tools.

The operator used the high-definition dual-imaging-while-drilling service to acquire high-resolution data in the interbedded formation. The EM and ultrasonic technologies highlighted faults and fracture orientations, layer bedding details, cross bedding and irregular surfaces. The data acquisition while drilling enabled detailed imaging of the coal layers and breakout phases.

Conclusion

The high-definition dual-imaging-while-drilling service improves reservoir understanding and augments well integrity. Combined with LWD technology, the service enables operators to achieve complete petrophysical, geological and geosteering objectives without using chemical sources.

Collocating image physics in a single tool provides a complete solution for detailed geological and borehole understanding in OBM environments in real-time while drilling, enabling efficient, informed drilling decisions and saving rig time. The real-time capability to transmit high-definition images adds a new dimension for operators to navigate through complex geology and maintain a high net-to-gross for the well being drilled. DC

TerraSphere is a mark of Schlumberger.