Halliburton introduces next-generation wireline logging sensor

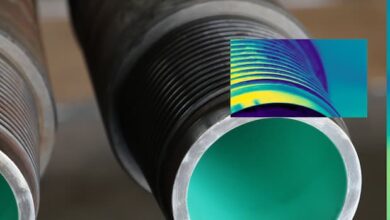

Halliburton has released the Xaminer Magnetic Resonance (XMR) Service, the industry’s only high pressure rated (35,000 psi) downhole sensor that provides comprehensive nuclear magnetic resonance measurements to improve reservoir insight. The service delivers more detailed formation data, including 2D and 3D fluid characterization, carbonate pore-size classification, unconventional analysis and permeability.

The service can acquire approximately eight times more data with less than half the power of traditional sensors. It also can be deployed in nearly every open-hole logging environment. XMR helps reduce an operator’s capital expenditures by eliminating the need for multiple sensors.

XMR acquires reservoir information in a single pass to increase reliability and improve data quality. One of the significant advantages of the sensor is its ability to log up and down a well. Operators can retrieve multiple logging passes in one trip, which is critical in poor hole conditions. The data fits seamlessly into advanced integrated analysis platforms, such as ShaleXpert, TurbiditeXpert, CarbondateXpert and TightGasXpert services.

“We designed the XMR service to help operators acquire more accurate well data to better evaluate production potential and increase the return on their investment,” Trey Clark, Vice President of Wireline and Perforating, said. “It can be deployed in mature fields, deepwater and unconventional reservoirs to provide superior formation resolution and help reduce field risks.”

Operators evaluating carbonate reservoirs for bypassed oil often observe unrecoverable reserves. An operator in West Texas used the XMR service to evaluate and confirm the presence of unrecoverable oil and avoided lost rig time trying to produce it. The data also validated reservoir zones that only produce saline water preventing costly production testing of these nonproductive zones.