Environment, Social & Governance

Westwood: More incentives needed to accelerate adoption of emission reduction upgrades on rigs

New research from Westwood Global Energy Group reveals that the availability of emission-lowering upgrades for offshore rigs has been on the rise but that adoption of these new technologies is slow outside of Norway and the US Gulf of Mexico due to limited regulatory and financial incentives.

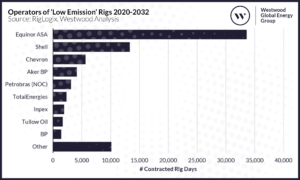

The report indicates that the biggest users of rigs fitted with emission reduction technology are those with ambitious emission goals of their own, driven largely by Equinor’s Norway and Brazil operations. Between 2020 and 2032, Equinor’s contracted days of low-emission upgraded rigs is 33,618 (92 rig years) compared with the combined number of days for all other operators, which is 43,600 rig days (119 rig years).

“Drilling contractors, and the industry as a whole, are starting to realize that oil and gas will be imperative to energy security over the coming years. But that doesn’t need to come at the detriment of the energy transition,” said Teresa Wilkie, RigLogix Director, Westwood. “Rig operators have ambitious Scope 1 reduction targets, and eco-friendly rig technology is keeping pace. The next step is for regulators to work with the industry to ensure that the framework is there to facilitate adoption of these new technologies in a financially sustainable way.”

She continued: “Norway is dominating as the biggest user of low-emission rigs, driven by the country’s carbon taxation regulations, as well as incentivization. Pair this with Equinor’s ambitious emission reduction targets and you have a ripe environment for low-emission rig adoption.”

Since the downturn in 2014, newbuild rig orders have almost come to a halt due to lack of demand, a mass oversupply of rigs and a resulting stack of newbuilds abandoned in shipyards with no work. There is still a lack of appetite to invest in costly newbuilds and, therefore, a deluge of “green” newbuild rig orders is unlikely. Instead, it is expected that more of the current fleet will be retrofitted for lower-emission operations.

“Some drilling contractors are at the beginning of their emissions reduction journeys, while others have been working on emission-reducing technologies, projects and studies for several years,” Ms Wilkie said. “By amalgamating the industry’s different and increasing efforts regarding this complex topic, we can better understand the trajectory of the industry, highlight new technologies and identify the areas of opportunity.”

ADNOC to apply blockchain to certify carbon intensity

Abu Dhabi National Oil Company (ADNOC) and Siemens Energy will pilot blockchain technology to certify the carbon intensity of a range of products. By using smart sensor data gathered from across ADNOC’s operational chain, the pilot will show how much CO2 was used to make products such as Murban crude, ammonia and aviation fuels. This information will be automatically recorded onto a decentralized blockchain ledger.

Such transparency will allow independent regulators to certify the carbon intensity of products.

Oil and gas expertise to help with well control for CCS

Norway’s state-owned Gassnova has awarded eDrilling NOK 10 million under its CLIMIT research program to develop well control software for carbon capture and storage (CCS). The project recognizes that today’s market does not have the well control technology needed to address the risks for underground leakage with full-scale CO2 storage. By leveraging its experience with well control of petroleum wells, eDrilling expects it can reduce the time and resources needed to launch reliable software for well control in CO2 wells. The development will also aim for easy integration with existing systems.

APA cuts upstream routine flaring in Egypt by 40%

APA Corp has achieved a compensation-linked ESG goal to reduce upstream routine flaring across Egypt operations by 40%. The goal was reached ahead of schedule and is the result of numerous emissions reduction projects executed in Egypt throughout 2022.

To achieve the 40% flare reduction goal, technical teams in Egypt identified a series of emissions reduction initiatives. The projects included the installation of new compressors to move gas from flaring to sales and implementing flare-to-power generation processes that move previously flared gas to power generation, which eliminated the need for diesel-based power generation.